Case Study: Successful Projects with Leading Custom Liquid Silicone Rubber Makers

Introduction:

The Power of Custom Liquid Silicone Rubber in Modern IndustryIn the rapidly evolving landscape of manufacturing, custom liquid silicone rubber (LSR) has emerged as an indispensable material for a multitude of high-performance applications. As industry leaders in custom silicone rubber manufacturing, we have consistently delivered innovative solutions that meet the most demanding specifications across sectors such as healthcare, automotive, electronics, and consumer goods. This comprehensive case study explores some of our most successful projects, demonstrating our expertise in design, material formulation, precision molding, and project management.

Why Choose Custom Liquid Silicone Rubber: Unmatched Properties for Complex Applications

Liquid silicone rubber offers exceptional thermal stability, flexibility, chemical resistance, and biocompatibility, making it ideal for applications requiring durability and precision. Our ability to customize formulations ensures that each project benefits from tailored physical and chemical properties—be it ultra-high temperature resistance for automotive components or medical-grade purity for healthcare devices.

Project 1: Advanced Medical Silicone Components for Life-Saving Devices

Client Challenge and Objectives

A leading medical device manufacturer sought a biocompatible, sterilizable silicone rubber solution for their next-generation infusion pump components. The key requirements included high purity, transparent material, dimensional stability, and resistance to sterilization processes such as autoclaving and gamma irradiation.

Our Approach and Solution

We developed a custom medical-grade liquid silicone rubber formulation aligned with ISO 10993 standards. This formulation featured:

High optical clarity for visual inspection

Enhanced tensile strength for mechanical stability

Excellent resistance to repeated sterilization cycles

Low extractables and leachables for patient safety

Using precision injection molding, we produced complex geometries with tight tolerances of ±0.05mm, ensuring seamless integration into the device assembly.

Outcome and Impact

The project resulted in a reliable, durable silicone component that withstood over 50 sterilization cycles without degradation. The client reported a significant reduction in manufacturing defects and improved device performance, ultimately leading to faster time-to-market and enhanced patient safety.

Project 2: High-Temperature Automotive Sealants and Gaskets

Client Challenge and Objectives

An automotive OEM required custom liquid silicone rubber for high-temperature seals and gaskets that could reliably operate in engine compartments, enduring temperatures up to 250°C while maintaining elasticity and chemical resistance.

Our Approach and Solution

Our team engineered a high-temperature resistant LSR formulation incorporating specialized fillers such as silica and ceramic particles, enhancing thermal stability. The manufacturing process leveraged multi-cavity molds to optimize production volume and consistency.

We designed custom profiles to fit specific engine components, ensuring perfect sealing under dynamic conditions.

Outcome and Impact

The resulting silicone gaskets demonstrated superior performance in rigorous testing, including thermal cycling, vibration, and chemical exposure. The client achieved longer service life for engine seals, reducing maintenance costs and vehicle downtime.

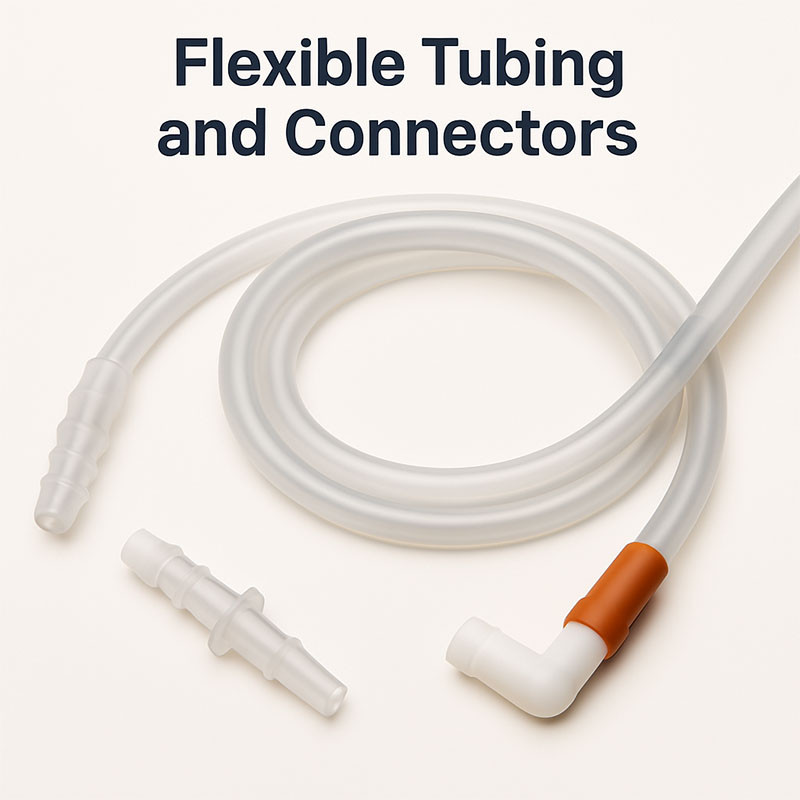

Project 3: Custom Silicone Medical Tubing for Drug Delivery Systems

Client Challenge and Objectives

A pharmaceutical company needed flexible, biocompatible silicone tubing for precise drug delivery, requiring smooth internal surfaces, chemical inertness, and compatibility with sterilization methods.

Our Approach and Solution

We developed a medical-grade liquid silicone formulation with low surface roughness and excellent flexibility. The tubing was manufactured with custom diameters and wall thicknesses using precision extrusion.

To ensure sterilization compatibility, the tubing was tested under autoclaving and ethylene oxide sterilization, with no compromise in mechanical or chemical integrity.

Outcome and Impact

The high-quality silicone tubing improved drug delivery accuracy, reduced occlusion risks, and enhanced patient safety. The client achieved regulatory compliance and market approval for their medical device.

Why Partner with Leading Custom Liquid Silicone Rubber Makers?

Tailored Formulations: We develop bespoke silicone compounds to meet specific mechanical, thermal, and chemical requirements.

Advanced Manufacturing: Our state-of-the-art injection molding, extrusion, and compression molding facilities ensure precision, repeatability, and scalability.

Regulatory Expertise:

We are well-versed in industry standards such as ISO, USP, and FDA requirements, ensuring compliance for medical and food-grade applications.Innovative Design Support:

Our team collaborates closely with clients from concept to production, optimizing design for manufacturability and cost efficiency.Sustainable Practices:

We prioritize eco-friendly materials and sustainable manufacturing processes to reduce environmental impact.Conclusion: Elevating Industries through Custom Silicone Rubber Excellence

Our portfolio of successful projects underscores our commitment to excellence, innovation, and client satisfaction. By leveraging cutting-edge technology, scientific expertise, and industry knowledge, we deliver custom liquid silicone rubber solutions that set the standard for performance and reliability.

Partnering with leading silicone rubber makers ensures your projects are supported by industry leaders dedicated to achieving your unique goals. Whether in healthcare, automotive, electronics, or consumer products, our custom silicone rubber solutions empower your business to excel in competitive markets.

Contact Us Today for Custom Liquid Silicone Rubber Solutions

Discover how our expertise can transform your next project. Reach out to our team for consultation, material development, and production services tailored to your specific needs.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883