Design plan formulation

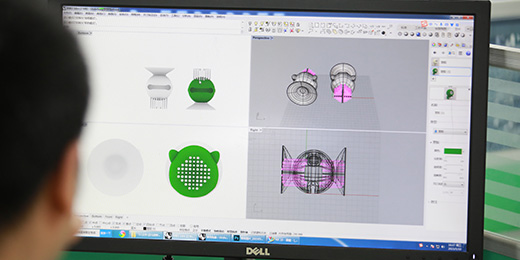

Analyze customer needs, consider actual application scenarios and production process requirements, formulate appearance and structural design plans that meet customer expectations, and ensure they are reasonable and feasible.

Analyze customer needs, consider actual application scenarios and production process requirements, formulate appearance and structural design plans that meet customer expectations, and ensure they are reasonable and feasible.

Based on customer aesthetic standards and market trends, taking into account the characteristics of silicone materials, we optimize the design of an appearance that meets the product positioning and brand image to enhance its market competitiveness.

Based on the appearance design, optimize the product structure, comprehensively consider functionality, stability and durability, and ensure good performance and user experience during use.

Comprehensively consider factors such as production process, material selection and manufacturing cost to evaluate cost-effectiveness, reasonably control costs to ensure product competitiveness and provide sustainable business value to customers.

Focus on product functional design, combining silicone material characteristics and process requirements to ensure that the product functions stably and reliably during use.

Focus on product performance optimization design, and improve product performance by selecting appropriate silicone materials, optimizing product structure and processing technology, etc.

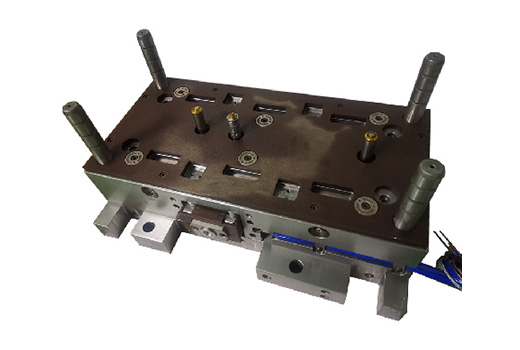

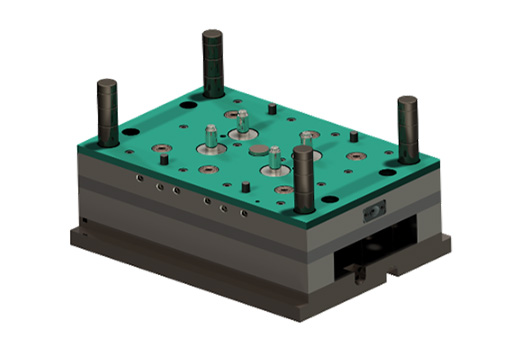

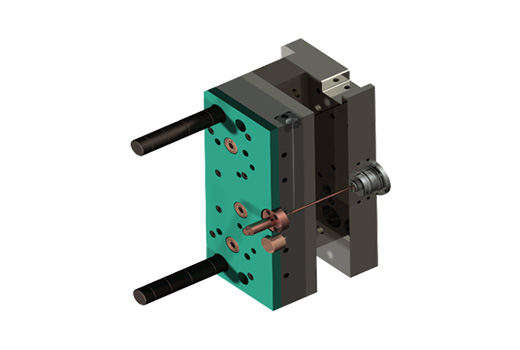

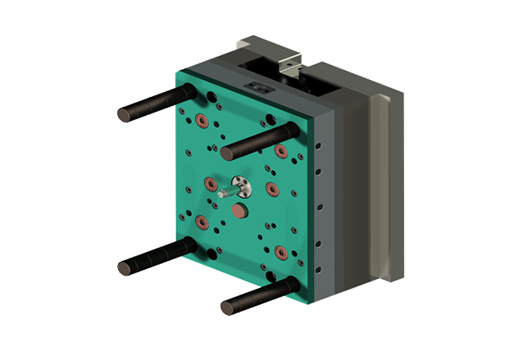

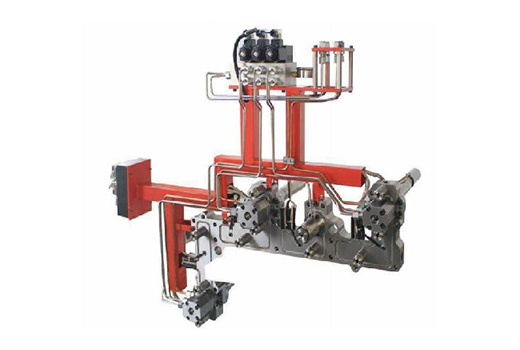

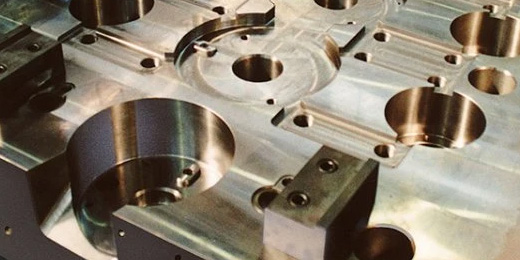

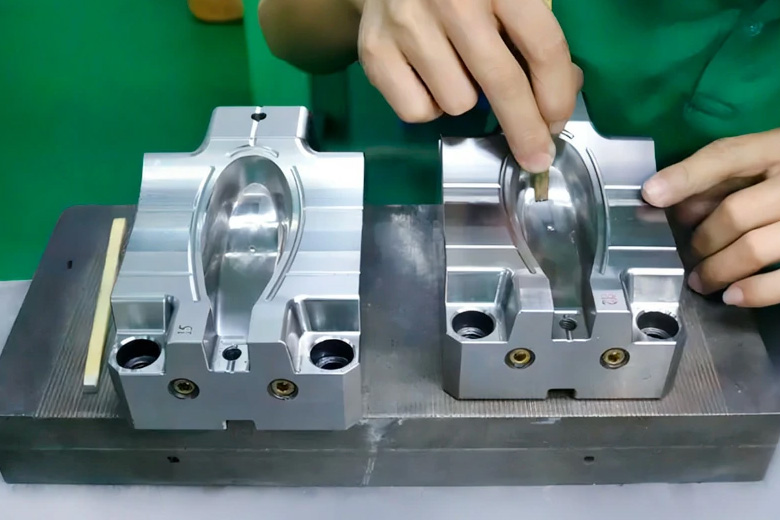

Design a reasonable and stable mould structure to meet the product appearance and structural design requirements, and ensure that the product shape, size and surface quality meet customer needs.

Select high-quality steel and choose appropriate processing technology according to product requirements and production environment to ensure the accuracy and quality of mold making.

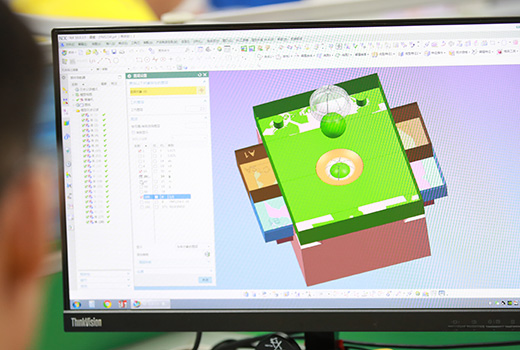

Develop a detailed mold manufacturing process planning to ensure that the mold manufacturing process proceeds in an orderly manner.

The sample mold production cycle is 3-7 days. Compared with mass production molds, the production cost is greatly reduced, providing you with fast samples and small-scale production solutions, saving capital investment to achieve product trial production and market verification.

Mass production mold productionFor mass-produced products, we provide professional mass production mold production services with a production cycle of about 20-25 days, ensuring high quality and high efficiency, and providing reliable guarantee for large-scale production.

Detailed quotation list for silicone mold making services:

Test and analyze molds to ensure that they meet the required specifications and can effectively produce high-quality parts.

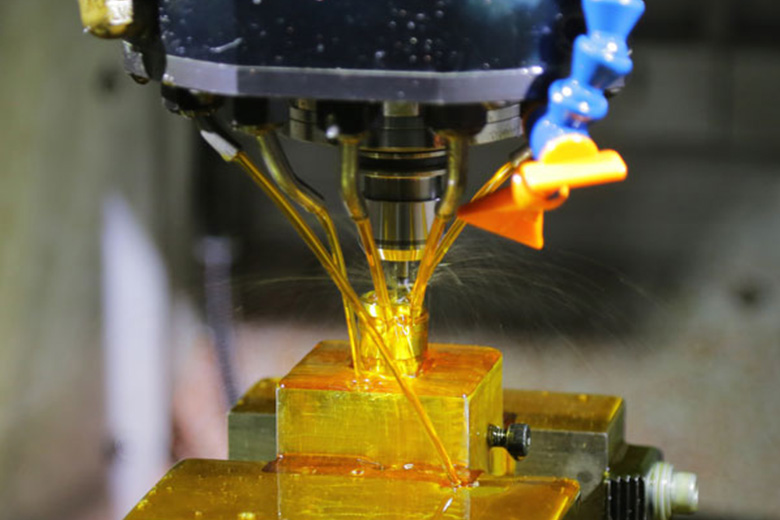

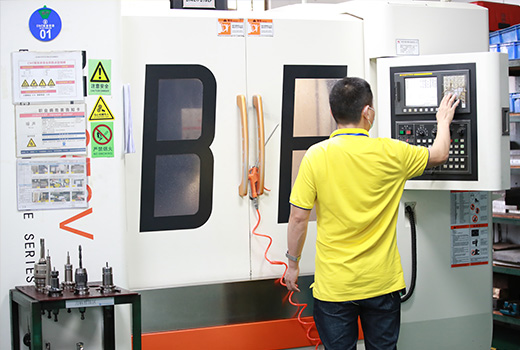

High-precision machining, fast machining speed, multi-axis linkage, automatic tool change, etc.

Precision EDM, high-speed machining, small detail machining capabilities, automatic electrode replacement, etc.

Responsible for the overall design and process planning of the mold, including PL line design, demoulding method and mold opening method selection, etc., to ensure the smooth progress of the mold making process.

Responsible for the operation and maintenance of CNC machining equipment to ensure the accuracy and quality of mold processing.

Responsible for the assembly, debugging and trial mold work of the mold to ensure stable operation of the mold and meet product quality standards.