5 Critical Factors When Selecting a Custom LSR Manufacturer

Introduction:

Choosing the right custom Liquid Silicone Rubber (LSR) manufacturer is a decision that profoundly influences the quality, cost-efficiency, and timeliness of your product development process. As industries such as medical devices, automotive, consumer electronics, and healthcare demand increasingly sophisticated and reliable silicone components, partnering with a trusted LSR manufacturer becomes paramount. Our comprehensive analysis delineates five critical factors that any enterprise must evaluate when selecting a custom LSR manufacturing partner.

1. Proven Expertise and Industry Experience in Custom LSR Production

The foundation of a reliable LSR manufacturer rests on extensive industry experience and a proven track record in custom silicone solutions. Manufacturers with decades of expertise demonstrate a profound understanding of material properties, processing techniques, and industry-specific standards.

Why this matters:

Technical mastery: Experienced manufacturers can innovate and optimize formulations tailored to your specific application, whether it involves medical-grade silicone, automotive seals, or consumer electronics.

Problem-solving ability:

Seasoned providers can anticipate challenges during production and offer effective solutions proactively.Regulatory compliance:

Long-standing companies are well-versed in industry standards such as ISO 10993 for medical applications or IATF 16949 for automotive, ensuring your products meet all regulatory requirements.Key considerations:

Review the manufacturer’s client portfolio, focusing on projects similar to yours.

Examine case studies and testimonials that showcase their problem-solving capabilities and innovative solutions.

Confirm certifications and awards that validate their expertise.

2. Superior Quality Control and Material Certification Standards

Quality assurance is non-negotiable when selecting a custom LSR manufacturer. The integrity of your final product depends heavily on the rigor of quality control (QC) processes and material certifications held by the manufacturer.

Why this matters:

Consistent product quality minimizes defects and rework, saving costs and reducing time-to-market.

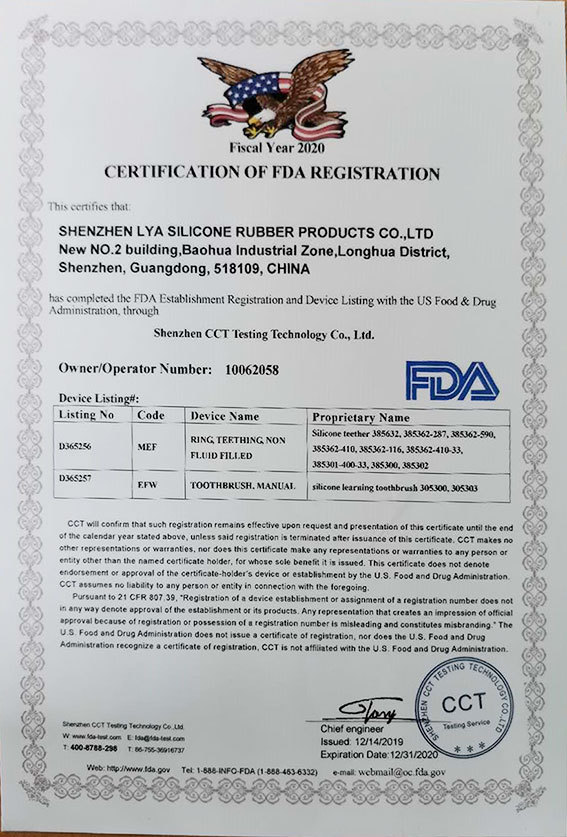

Material certifications such as REACH, RoHS, FDA compliance, and ISO 9001 ensure that the silicone rubber conforms to global safety and environmental standards.

Traceability of raw materials guarantees full transparency, which is especially critical in medical and automotive applications.

Key considerations:

Investigate the manufacturer’s QC protocols, including incoming raw material inspection, in-process testing, and final product validation.

Request certification documents for all materials used.

Ensure they utilize advanced testing equipment like FTIR spectroscopy, durometer testing, and compression set analysis.

3. Advanced Manufacturing Capabilities and Customization Flexibility

A cutting-edge LSR manufacturer must possess state-of-the-art equipment and flexible production lines capable of accommodating complex geometries, small batch runs, and high-volume productions.

Why this matters:

Precision molding and microfabrication capabilities enable the creation of detailed, intricate components required in medical devices or electronics.

Rapid prototyping services shorten product development cycles, allowing for quick iterations and design validation.

The ability to customize formulations—such as adding colorants, antimicrobial agents, or special fillers—ensures your product meets specific performance criteria.

Key considerations:

Confirm the manufacturer’s equipment inventory, including injection molding presses, compression molding machines, and cleanroom facilities.

Assess their ability to handle small batch runs and large-scale production simultaneously.

Evaluate their R&D capabilities for formulation development and material innovation.

4. Commitment to Regulatory Compliance and Industry Standards

In sectors like medical, automotive, and food contact applications, regulatory compliance is crucial. The chosen LSR manufacturer must demonstrate strict adherence to relevant industry standards and regulatory frameworks.

Why this matters:

Ensures product safety, effectiveness, and marketability across global markets.

Non-compliance can lead to product recalls, legal liabilities, and brand damage.

A compliant manufacturer simplifies your certification process and regulatory audits.

Key considerations:

Verify their compliance certifications such as ISO 13485 (medical devices), IATF 16949 (automotive), and FDA registration for medical-grade silicone.

Confirm their ability to produce traceable, documented batches suitable for regulatory submissions.

Ensure they are up-to-date with latest regulations and industry standards.

5. Robust Supply Chain and Lead Time Management

The timeliness of your project hinges on the manufacturer’s supply chain robustness and lead time efficiency. A dependable LSR supplier should provide transparent scheduling, inventory management, and flexible logistics solutions.

Why this matters:

Delayed deliveries can cause production halts, cost overruns, and missed market opportunities.

A well-organized supply chain ensures raw materials availability and on-time production cycles.

The capacity to scale production rapidly in response to demand fluctuations is a distinct advantage.

Key considerations:

Review the manufacturer’s lead time estimates for prototypes and bulk production.

Assess their inventory management systems and supplier relationships.

Confirm their logistics capabilities, including shipping options, customs clearance, and global distribution.

Why SiliconePlus.net Meets All Five Standards of an Ideal Custom LSR Manufacturer

1. Proven Expertise and Industry Experience

SiliconePlus (LYA Silicone) has over a decade of experience specializing in custom Liquid Silicone Rubber (LSR) solutions. Our engineering team combines deep material knowledge with advanced process design to deliver precision-molded components for medical, automotive, baby care, and 3C electronics industries. We have successfully supported numerous OEM/ODM projects for international clients, proving our capability in both innovation and reliability.

2. Superior Quality Control and Certified Materials

Every product at SiliconePlus is manufactured under ISO 9001 and ISO 13485 quality management systems. Our materials comply with FDA, REACH, and RoHS standards, ensuring global safety and environmental compatibility. From raw material inspection to final product testing (including hardness, tensile, compression, and biocompatibility analysis), we maintain full traceability and consistency across production batches.

3. Advanced Manufacturing Capabilities and Customization Flexibility

Equipped with fully automated LSR injection molding systems, cleanroom environments, and precision micro-molding technology, SiliconePlus can handle both low-volume prototypes and mass production runs. We offer custom formulation, color matching, and overmolding services for complex multi-component designs, ensuring your parts achieve optimal mechanical and aesthetic performance.

4. Full Regulatory Compliance and Industry Standards

SiliconePlus adheres strictly to ISO 13485 (medical devices) and IATF 16949 (automotive) standards. Our LSR products are biocompatible, hypoallergenic, and safe for skin contact, meeting the demanding requirements of global markets. This commitment ensures that every batch produced is documentation-ready for regulatory audits or certification submissions.

5. Robust Supply Chain and Reliable Lead Time Management

With a streamlined in-house production system, stable raw material partnerships, and global logistics support, SiliconePlus guarantees timely delivery for both prototype and large-scale orders. Our flexible scheduling and transparent communication help clients reduce downtime, control costs, and accelerate their product launch cycles.

Conclusion: Your Path to Selecting the Optimal Custom LSR Manufacturer

In conclusion, selecting a premier custom Liquid Silicone Rubber manufacturer requires meticulous evaluation across experience, quality, capabilities, compliance, and supply chain resilience. The right partner not only provides superior materials and advanced manufacturing but also ensures regulatory adherence and timely delivery, ultimately empowering your business to innovate confidently and compete effectively in your industry.

By prioritizing these five critical factors, your organization can forge a strategic partnership that elevates your product development process, guarantees product excellence, and secures your position as a market leader in the liquid silicone rubber sector.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883