Silicone Overmolding Products

At Siliconeplus, we specialize in the production of Silicone Overmolding Products, offering innovative and custom solutions for a wide range of industries. As a professional silicone overmolding manufacturer, we combine silicone with materials such as plastic, metal, and ceramics, ensuring superior product performance and durability. Our advanced processes ensure precise overmolding, delivering products that meet the highest quality standards for applications in automotive, medical devices, electronics, and more. With a focus on customization and functionality, we provide tailored solutions that enhance product value and usability.

68 results

ViewShowcase

High-quality LSR overmolded medical components with custom OEM/ODM silicone parts, biocompatible, and precision-engineered.

Siliconeplus provides custom silicone overmolding with durable materials, and reliable mass production for automotive parts.

Custom automotive silicone parts manufacturer specializing in LSR molding and overmolding solutions for OEM applications.

Custom medical-grade liquid silicone breathing masks by SiliconePlus ensure safety, and OEM/ODM customization.

High-precision silicone automotive parts with metal inserts, vibration resistance, custom OEM solutions for harsh environments

LSR overmolding enables durable, and customizable silicone components with superior sealing, and efficiency for B2B industries

Custom LSR silicone overmolding for automotive parts OEM silicone manufacturer providing customizable solutions

Custom LSR silicone overmolding for beauty & health care devices OEM silicone manufacturer, high-performance customizable part

SiliconePlus manufactures custom medical liquid silicone rubber (LSR) components using biocompatible materials and ISO 13485 compliant processes for reliable OEM and ODM production.

Custom mold development services for silicone products, supporting OEM solutions with tooling and flexible customization.

Custom silicone rubber components including plugs, gaskets, protection, and OEM industrial applications.

Premium silicone weather stripping providing durable automotive sealing, custom extrusion, OEM/ODM support.

Durable, heat-resistant silicone sealing rings and flat gaskets designed for reliable, customizable industrial sealing.

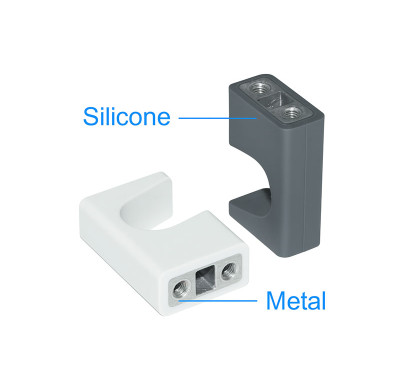

High-precision silicone overmolded metal parts with strong bonding, and durable LSR insert molding for custom OEM projects.

Durable automotive-grade molded silicone cover & plug for EV charger ports — weather-proof, high-performance protection

Custom silicone rubber parts manufacturer offering OEM/ODM molding, LSR injection, and high-quality silicone accessories.

Custom silicone gasket for SIM card tray, providing precise waterproof and dustproof sealing for mobile and electronic devices.

Medical grade silicone facial mask with LSR molding— enhances LED therapy, locks moisture, and fits perfectly for skincare use.

Custom liquid silicone Bluetooth earphone case with soft-touch, shockproof,OEM & ODM silicone molding expert.

Eco-Friendly Silicone Dog Treat Training Pouch — Portable, Waterproof & Durable Snack Bag for Outdoor Pet Walking and Training

Soft anti-slip silicone eyewear ear hooks provide comfort and stability for glasses, size, and logo for OEM/ODM brands.

Custom silicone LED phototherapy mask made with medical-grade LSR, flexibility, and OEM customization for skincare brands.

Premium silicone eyeglass temple covers with non-slip grip, comfort, and protection. Universal fit, easy to clean, custom colors & OEM/ODM service.

Custom silicone refractive lamp made from moldable optical silicone elastomers, offering high transparency, UV resistance.

Please send your message to us

- *Phone

- *Title

- *Content

Contact Person