Medical Grade Silicone Overmolding

Why Medical Device Manufacturers Choose Silicone Overmolding

Excellent Biocompatibility

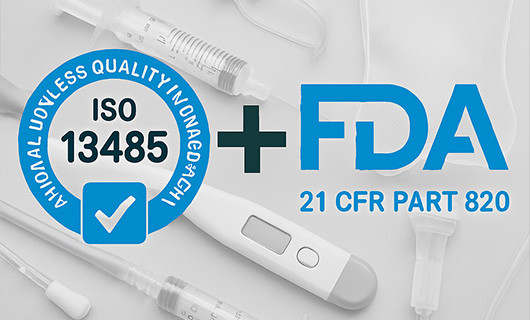

Medical-grade silicone complies with international biocompatibility standards such as ISO 13485 and USP Class VI, and is suitable for medical devices that come into contact with the human body.

High and Low Temperature Resistance

Adaptable to the temperature range of -50℃ to +200℃, it can be repeatedly sterilized at high temperatures and work stably for a long time.

Chemical Resistance

Silica gel has good chemical resistance, is not easily corroded by chemicals such as acids and alkalis, and has good stability.

Sealing and Waterproof Performance

Overmolding can provide a complete encapsulation and sealing effect, meeting the requirements of IP67 and above waterproof and dustproof levels.

Improve User Experience

The use of silicone overmolding on the outer surface of medical devices can enhance grip, prevent slipping, reduce hand fatigue, and improve the user experience of patients and medical staff.

High Production Efficiency

LSR one-shot molding technology can reduce the number of components, simplify assembly, save production costs and increase production speed.

Applications of Medical Grade Silicone Overmolding

Silicone Overmolding for Surgical Instruments

Adding grip, color coding, and ergonomic comfort to scalpels, forceps, or handle assemblies.

Medical implant silicone overmolding

Providing a soft, biocompatible barrier over titanium, PEEK, or other implantable substrates.

Diagnostic & Monitoring Devices

Creating waterproof, tactile housings for wearable health trackers or home-use medical electronics.

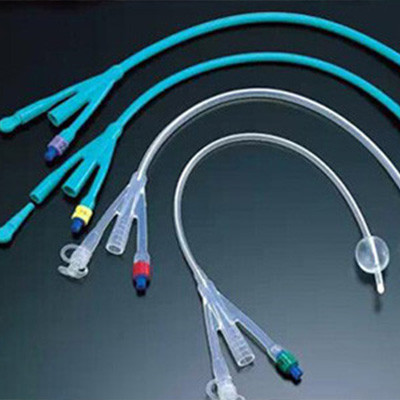

Catheter & Tubing Connections

Seamless overmolding of Y-connectors, port seals, and valve components.

Discover Premium Medical Grade Silicone Overmolding Products at SiliconePlus

16 results

ViewShowcase

High-quality LSR overmolded medical components with custom OEM/ODM silicone parts, biocompatible, and precision-engineered.

Custom medical-grade liquid silicone breathing masks by SiliconePlus ensure safety, and OEM/ODM customization.

SiliconePlus manufactures custom medical liquid silicone rubber (LSR) components using biocompatible materials and ISO 13485 compliant processes for reliable OEM and ODM production.

Eco-Friendly Silicone Dog Treat Training Pouch — Portable, Waterproof & Durable Snack Bag for Outdoor Pet Walking and Training

Medical-grade spiral silicone plug by Siliconeplus offers excellent sealing, and durability for diverse applications.

medical grade silicone face mask, FDA/ISO13485 certified, IP68 waterproof, customizable for respirators & CPAP devices.

Custom medical-grade silicone balloon with LSR molding offers flexible, and biocompatible fluid control for medical devices.

Our products can be customized with LOGO,size and packaging according to customer needs, e-commerce sellers and wholesalers.

At SiliconePlus, we specialize in high-precision medical silicone molding and medical-grade rubber components manufacturing.

High-Precision Silicone Overmolding for Medical & Industrial Use

Real silicone factory. Highly automated production line. ISO:13485, FDA, LFGB certified. Offer Cost-Effective Solutions in Felds Such as Baby Care, Kitchen and Houseware Items.

Medical grade raw materials are non-toxic and tasteless, ISO13485 production system certification, human facial mechanics process design. Processing form: OEM/ODM/customized according to samples and drawings Application industry: medical industry, outdoor protection Product features: medical grade products, non-toxic and tasteless, soft and skin-friendly, close to the face

Liquid Silicone Rubber Injection Molding is an advanced manufacturing process that is particularly suitable for the medical industry. Medical Grade Silicone Overmolding technology enables precision manufacturing of medical devices, ensuring their high safety and reliability during use. The combination of these two processes not only improves the durability of the product, but also meets strict medical standards, making medical grade silicone products have better biocompatibility and performance, making them an ideal choice for medical device manufacturing.

Liquid Silicone Rubber Injection Molding is an advanced manufacturing process that is particularly suitable for the medical industry. Medical Grade Silicone Overmolding technology enables precision manufacturing of medical devices, ensuring their high safety and reliability during use. The combination of these two processes not only improves the durability of the product, but also meets strict medical standards, making medical grade silicone products have better biocompatibility and performance, making them an ideal choice for medical device manufacturing.

Silicone overmolding is a vital process in the medical industry, providing reliable and high-quality solutions for various medical devices and components. This technique involves bonding silicone over substrates like metals or plastics, enhancing the performance, durability, and safety of medical products.

We are a professional silicone product custom processing source factory, focusing on providing customers with high-quality silicone products and innovative customized solutions. With rich experience and advanced technology, we are committed to meeting the strict requirements of the medical industry and providing users with reliable, comfortable and powerful silicone + FPC customized products.

Discover Premium Medical Grade Silicone Overmolding Products at SiliconePlus

Our complete and rigorous medical grade silicone overmolding process enables high-yield production of biocompatible silicone overmolding components with unmatched reliability.

step 01

Material Selection & Compliance

We assist in selecting the most suitable medical-grade silicone formulations, ensuring compliance with FDA, ISO, and global regulatory requirements.

step 02

Rapid Prototyping & Pilot Runs

Quick-turn prototyping and low-volume pilot production help accelerate design validation and reduce time-to-market.

step 03

Cleanroom Manufacturing

Production is carried out in ISO Class 7/8 cleanrooms to prevent contamination and meet stringent medical device standards.

step 04

Secondary Processing & Assembly

We provide value-added services such as laser marking, over-assembly, and multi-component integration.

step 05

Packaging & Sterilization Support

Custom packaging solutions and sterilization-compatible materials ensure safety and convenience for end users.

step 06

Supply Chain & On-Time Delivery

Robust logistics and supply chain management guarantee stable capacity, traceability, and reliable on-time delivery.

Why Choose SiliconePlus for Medical Silicone Overmolding

We have specialized in high-precision medical silicone solutions for over 20 years. Our custom medical grade silicone overmolding services provide unmatched expertise from concept to mass production.

Custom Engineering Support

We work closely with your R&D team to design silicone overmolded components that meet both performance and regulatory requirements.

Advanced Manufacturing

Our automated liquid silicone rubber (LSR) injection and compression molding lines deliver stable, repeatable results at scale.

Cleanroom Production

All medical silicone overmolding is performed in certified cleanrooms, minimizing the risk of contamination.

Comprehensive Testing

Every component undergoes dimensional, adhesion, tensile, and aging tests to meet or exceed international medical standards.

Regulatory Compliance

Our FDA-registered and ISO 13485-certified facilities ensure that all products comply with the strictest safety and quality standards.

Supply Chain & On-Time Delivery

We have established a robust supply chain management system to ensure raw material traceability, stable capacity, and reliable on-time delivery to meet market demands.

Customer Testimonials About Our Medical Silicone Overmolding Solutions

Medical Grade Silicone Overmolding Insigts & Guidelines

In today’s rapidly evolving healthcare landscape, product safety remains paramount. Manufacturers are increasingly turning to medical-grade liquid silicone rubber (LSR) to meet the stringent demands of biocompatibility, durability, and safety. This advanced material offers unparalleled advantages in the production of medical devices, wearable health products, and surgical instruments, ensuring that safety is embedded at every stage of product development.

LSR's combination of biocompatibility, durability, flexibility, and chemical resistance makes it an ideal choice for respiratory applications, ranging from ventilator components to nasal masks and catheters. With the growing demands of healthcare, especially amidst the global health crisis, the development of cutting-edge LSR products tailored for respiratory devices has become a focus of innovation.

As the healthcare industry evolves at an unprecedented pace, Liquid Silicone Rubber (LSR) remains at the forefront of medical device innovation. The year 2025 promises significant breakthroughs driven by technological advancements, material science innovations, and a relentless focus on patient safety and device efficiency. This comprehensive exploration delineates the emerging trends in Medical LSR technologies that are set to revolutionize the sector.

FAQs About Medical Grade Silicone Overmolding

What is medical-grade silicone overmolding?

Medical-grade silicone overmolding is a process in which medical-grade silicone is injected into the surface of another material (such as plastic, metal, or electronic components) to form a soft, durable protective silicone layer. This technique is commonly used in the manufacture of medical devices, surgical tools, implants, and other medical products requiring high standards of biocompatibility.

How does medical-grade silicone overmolding differ from regular silicone?

Medical-grade silicone is a silicone material that meets strict medical standards (such as ISO 10993 and USP Class VI), guaranteeing high biocompatibility, non-toxicity, and chemical resistance. Regular silicone may not meet these biocompatibility and durability standards and is generally unsuitable for medical applications.

What are the advantages of medical-grade silicone overmolding?

Medical-grade silicone overmolding offers several advantages, including:

High biocompatibility: It will not cause adverse reactions in the human body and is suitable for medical products that come into long-term contact with skin or human tissue.

High durability: It can withstand high temperatures, chemicals, UV rays, and physical abrasion.

Anti-slip and Comfort: Provides improved feel and anti-slip properties, particularly suitable for medical devices and tools.

Softness and Elasticity: Provides increased comfort and flexibility for medical devices.

What medical products are suitable for medical-grade silicone overmolding?

Medical-grade silicone overmolding is widely used in a variety of medical products, including:

Surgical tools and instruments

Artificial joints and implants

IV tubes, catheters, and medical fittings

Respiratory masks and medical masks

Personal care products (such as blood glucose meters, hearing aids, etc.)

How to choose the right medical-grade silicone overmolding service provider?

When choosing the right supplier, you can consider the following:

Certifications and Standards: Ensure that their products comply with relevant international standards such as ISO and USP and have the necessary quality certifications.

Production Capacity: Select a supplier with advanced equipment and technology that can provide high-precision overmolding services.

Experience and Expertise: Experience in the relevant industry, particularly in the medical device field, allows them to provide customized solutions based on your needs.

Please send your message to us

- *Phone

- *Title

- *Content

Contact Person