Liquid Precipitated Silicone

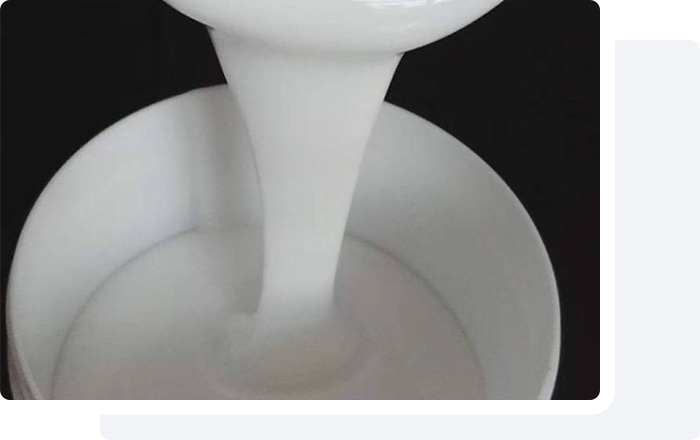

Precipitated silica is a type of silica prepared by the sol-gel process. In this process, a silicate solution (such as ethyl silicate) is gelled under specific conditions to form a gel, which is then converted into solid silica by heat or chemical treatment. This preparation method makes the microstructure of the silica very uniform and has good physical and chemical properties. It is often used to prepare high-performance silica materials, such as silica fillers, coatings, and molded products.

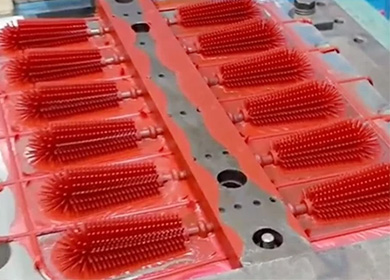

- Uniform Microstructure

- High Stability Of Inished Products

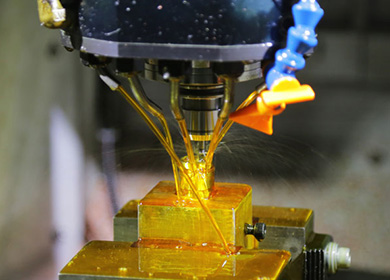

- Strong Process Controllability