Case Studies: Successful Products Made with Liquid Silicone Rubber (LSR)

Introduction: The Power of Liquid Silicone Rubber in Modern Manufacturing

Liquid Silicone Rubber (LSR) has revolutionized the manufacturing landscape across diverse industries. Its unique combination of flexibility, durability, temperature resistance, and biocompatibility makes it an ideal material for a wide array of high-performance products. As a leading innovator in the field, we have compiled extensive case studies illustrating how top-tier companies harness the exceptional properties of LSR to create market-leading products. These examples serve as a blueprint for manufacturers seeking to elevate their product offerings through advanced silicone technology.

Understanding Liquid Silicone Rubber: The Foundation of Innovation

Liquid Silicone Rubber (LSR) is a high-purity, heat-curable silicone elastomer supplied in a liquid form. Its two-component system allows for precision molding via injection molding, offering complex geometries, fine detail reproduction, and repeatability. The key

attributes of LSR include:

1.Exceptional flexibility and elasticity

2.High temperature resistance (up to 300°C)

3.Chemical inertness and biocompatibility

4.Excellent electrical insulation properties

5.Outstanding weather and UV resistance

6.Ease of sterilization, making it ideal for medical applications

7.These properties enable the production of robust, versatile, and high-quality products that meet demanding industry standards.

Leading Industries Leveraging LSR for Product Innovation

1.Medical and Healthcare Devices

LSR's biocompatibility and sterilization capabilities have made it a material of choice for medical devices such as catheters, wearable sensors, and prosthetics. Its ability to withstand repeated sterilization cycles without degradation ensures safety and longevity.

2.Consumer Electronics

The flexibility, water resistance, and temperature stability of LSR have been pivotal in manufacturing wearable devices, smartphone accessories, and health monitoring gadgets. These products require materials that can endure daily wear and environmental exposure.

3.Automotive and Aerospace

In these industries, LSR is used for seals, gaskets, and insulation components due to its thermal stability and resistance to automotive fluids. Its lightweight nature contributes to overall vehicle efficiency.

4.Baby and Personal Care Products

LSR's non-toxic and hypoallergenic properties make it suitable for baby bottle nipples, pacifiers, and personal care applicators. Its softness and durability provide comfort and safety.

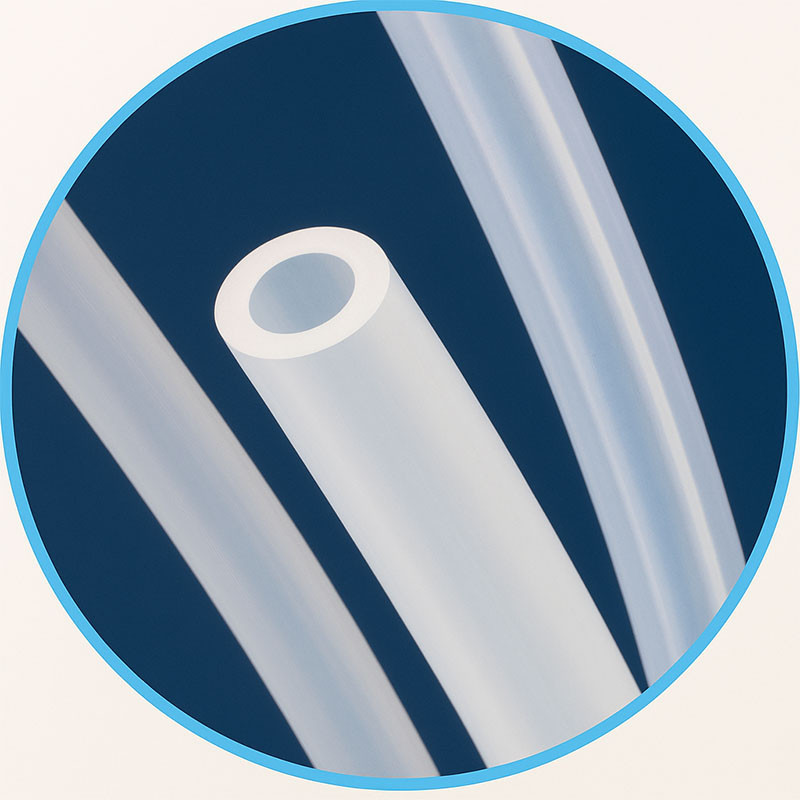

Case Study 1: Development of Medical Silicone Catheters

Background and Challenges

The demand for biocompatible, flexible, and reliable catheters has increased dramatically. Traditional materials faced issues with chemical degradation, limited flexibility, and sterilization challenges. Our client, a leading medical device manufacturer, sought to develop a high-performance silicone catheter that could withstand multiple sterilization cycles while maintaining patient safety.

Solution and Implementation

Utilizing high-purity LSR, we engineered a catheter with complex internal geometries and smooth surface finishes. The injection molding process was optimized for precise dimensional control and consistent quality. The chosen LSR formulation provided superior biocompatibility and chemical inertness, ensuring safety during prolonged use.

Key steps

Selection of medical-grade LSR compliant with ISO 10993 standards

Implementation of micro-molding techniques for fine features

Conducting rigorous sterilization testing (EO, steam, plasma)

Validation of flexibility, compression set, and biocompatibility

Results and Impact

The result was a durable, flexible, and biocompatible silicone catheter capable of withstanding multiple sterilization cycles without loss of performance. The product received FDA approval and became a market leader, offering improved patient comfort and reduced complication rates

Case Study 2: Manufacturing of Waterproof Wearable Fitness Devices

Background and Challenges

In the rapidly expanding wearable technology market, manufacturers face the challenge of creating devices that are waterproof, flexible, and comfortable. The key was to develop a soft, durable housing that could resist sweat, water ingress, and mechanical stress.

Solution and Implementation

We employed LSR injection molding to produce customized, seamless enclosures for fitness trackers and smartwatches. The LSR formulation was chosen for its excellent water resistance, UV stability, and soft tactile feel.

Design considerations included

Achieving precise fit for electronic components

Incorporating silicone seals for water ingress protection

Ensuring flexibility for wearer comfort

Selecting colorants compatible with LSR for aesthetic appeal

Results and Impact

The resulting products showcased superior waterproofing (IP68 rating), enhanced durability, and user comfort. These features contributed to market differentiation, increased consumer satisfaction, and higher sales volumes.

Case Study 3: Automotive Seals and Gaskets with LSR

Background and Challenges

Automotive manufacturers demand reliable sealing solutions that can endure extreme temperatures, chemical exposure, and mechanical wear. The challenge was to produce seals and gaskets that meet these rigorous standards while maintaining cost-effectiveness.

Solution and Implementation

Using liquid silicone rubber, we developed customized seals with complex geometries via precision injection molding. The LSR formulations were tailored for high temperature resistance and chemical inertness.

Key features:

Compression set resistance to maintain sealing integrity

Excellent elasticity for easy installation

UV and ozone resistance for long-term durability

Compatibility with automotive fluids

Results and Impact

The automotive seals demonstrated superior performance under extreme operational conditions, significantly reducing leakage issues and maintenance costs. The adoption of LSR-based seals improved overall vehicle reliability and customer satisfaction.

Innovations in LSR Manufacturing: Advancements Driving Success

Recent technological advancements have further expanded the scope of LSR applications. High-precision injection molding equipment, advanced formulations, and sophisticated mold designs now enable manufacturers to produce intricate and high-quality components efficiently.

Emerging trends include:

1.Multi-material molding, combining LSR with other polymers for complex assemblies

2.Color customization through advanced pigment integration

3.Miniaturization for micro-scale devices

4.Eco-friendly formulations aligning with sustainability goals

5.These innovations allow companies to push the boundaries of what is achievable with LSR, opening new markets and product categories.

Choosing the Right Partner for LSR Product Development

Partnering with an experienced liquid silicone rubber manufacturer is crucial for success. A reliable partner provides:

1.Expertise in formulation development tailored to specific application needs

2.State-of-the-art equipment for high-precision injection molding

3.Rigorous quality control to ensure consistency and compliance

4.End-to-end support from design to production and post-processing

5.By leveraging industry-leading capabilities, manufacturers can accelerate product development, reduce costs, and ensure superior quality.

Conclusion: Unlocking Potential with Liquid Silicone Rubber

The showcased case studies exemplify the versatility, performance, and innovative potential of Liquid Silicone Rubber in creating successful products across multiple industries. As market demands evolve, the ability to harness LSR's unique properties will remain a key differentiator for manufacturers seeking competitive advantage.

Investing in advanced LSR solutions not only enhances product quality but also fosters innovation, safety, and sustainability. We are committed to supporting your journey toward cutting-edge silicone-based products that set new standards in performance and reliability.

Contact Us for Customized LSR Solutions

Explore how our expertise in Liquid Silicone Rubber can elevate your product line. Reach out today for consultation, formulation development, and manufacturing partnerships that deliver excellence.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883