Comparing Liquid Silicone Rubber to Traditional Silicone: What You Need to Know

Comparing Liquid Silicone Rubber to Traditional Silicone: What You Need to Know

In the rapidly evolving world of silicone materials, understanding the distinctions between liquid silicone rubber (LSR) and traditional silicone is essential for manufacturers, engineers, and product designers aiming to optimize performance, durability, and cost-efficiency. This comprehensive guide delves deep into the properties, manufacturing processes, applications, advantages, and limitations of both materials, equipping you with the knowledge to make informed decisions.

Understanding Silicone Materials: An Overview

Silicone, a synthetic polymer made from silicon, oxygen, carbon, and hydrogen, has been a staple in various industries including medical, automotive, electronics, and consumer goods. The two primary forms—liquid silicone rubber (LSR) and traditional silicone—serve different purposes, shaped by their unique characteristics and production methods.

What Is Liquid Silicone Rubber (LSR)?

Liquid Silicone Rubber (LSR) is a highly versatile, two-part, addition-cure silicone elastomer that is processed in its liquid form. It is primarily used in injection molding techniques, enabling mass production of precise, complex-shaped components with excellent surface finishes.

Key Characteristics of LSR:

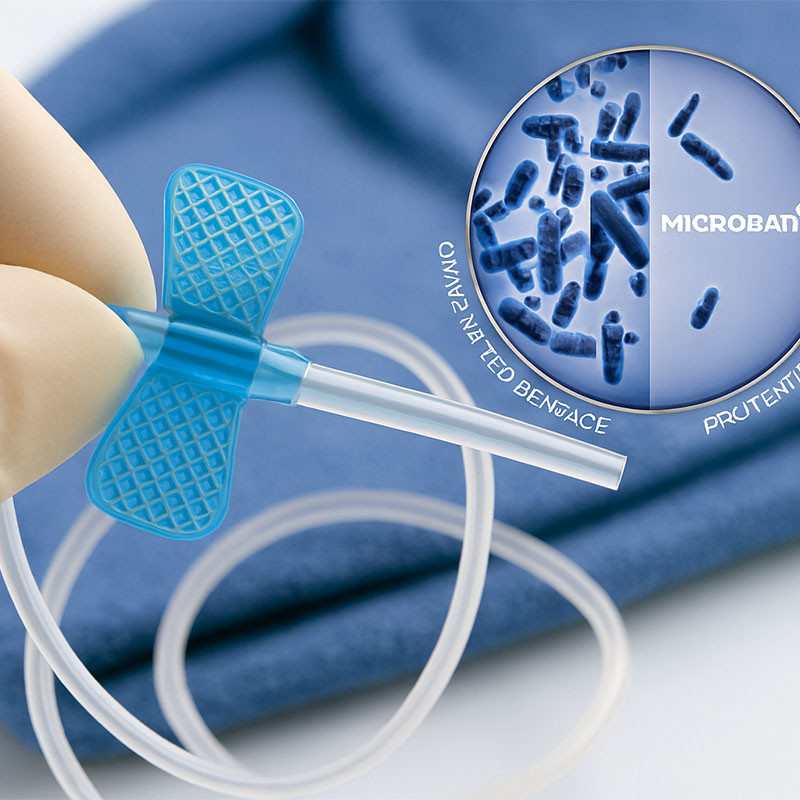

1.High purity and biocompatibility, making it ideal for medical applications.

2.Excellent thermal stability, withstanding temperatures from -50°C to +250°C.

3.Superior clarity and transparency.

4.Rapid curing times during manufacturing.

5.Low viscosity, facilitating intricate mold designs and detailed features.

6.Exceptional electrical insulation properties.

What Is Traditional Silicone?

Traditional silicone, often referred to as solid silicone rubber or RTV (room temperature vulcanizing) silicone, is typically supplied as pre-formed sheets, blocks, or pastes that cure at room temperature or with heat. It is widely used for prototyping, sealing, insulation, and mold-making.

Key Characteristics of Traditional Silicone:

1.Versatile forms:sheets, tubes, pastes, and molds.

2.Ease of use:suitable for hand-molding, casting, and sealing.

Lower equipment requirements.

Good flexibility and weather resistance.

Limited precision compared to LSR, especially for complex geometries.

Good electrical insulation.

Manufacturing Processes: LSR vs. Traditional Silicone

Liquid Silicone Rubber (LSR) Manufacturing

LSR is produced via addition curing (addition-crosslinking), involving two components that react at elevated temperatures.

The process includes:

1.Mixing:Precise blending of base polymer and curing agent.

2.Injection Molding:The liquid mixture is injected into molds under high pressure.

3.Curing:Rapid vulcanization occurs within seconds to minutes.

4.Demolding:Finished parts are ejected with high dimensional accuracy.

Advantages of LSR Manufacturing:

1.High-volume production efficiency.

2.Consistent quality and tight tolerances.

3.Ability to produce complex geometries with intricate details.

4.Minimal post-processing required.

5.Traditional Silicone Manufacturing

1.Traditional silicone is typically processed through:

Hand-molding or casting of pre-formed sheets or pastes.

Vulcanization at room temperature or with heat.

Limited automation compared to LSR injection molding.

Post-curing and finishing often necessary for complex parts.

2.Limitations:

Lower production speeds.

Less precise dimensional control.

More labor-intensive.

Key Differences in Properties and Performance

| Property | Liquid Silicone Rubber (LSR) | Traditional Silicone |

Form | Liquid, injection-moldable | Solid, sheet, paste, or moldable |

| Processing | Injection molding, rapid cure | Hand-molding, casting, room temperature vulcanization |

Precision | High, suitable for complex geometries | Moderate, better for simple shapes |

| Surface Finish | Very smooth, transparent options | Variable, often matte or opaque |

Temperature Resistance | -50°C to +250°C | -50°C to +200°C (varies) |

| Biocompatibility | Excellent, medical-grade options available | Good, but less consistent |

Cost for Mass Production | Lower per unit at high volumes | Higher labor and time costs |

Electronics: Insulating and sealing properties suit connectors, housings, and waterproofing elements.

Consumer Goods: Precise, transparent, and flexible parts like wearable devices, kitchen utensils, and personal care products.

Traditional Silicone Applications

Seals and Gaskets: Weather-resistant and flexible, used in building insulation, window seals.

Molds and Prototypes: Cost-effective for small batch production.

Electrical Insulation: Used in coatings and encapsulants.

Advantages of Liquid Silicone Rubber Over Traditional Silicone

1.Enhanced Precision and Detail:LSR's ability to reproduce complex features with tight tolerances surpasses traditional silicone, making it the preferred choice for high-precision components.

2.Faster Production Cycle: Injection molding with LSR significantly reduces lead times, especially in mass production environments.

3.Superior Surface Finish:LSR parts exhibit smooth, glossy surfaces without additional finishing.

4.Greater Material Purity and Biocompatibility:Ideal for medical and food-grade applications.

5.Better Dimensional Stability:LSR maintains shape and size over time, even under extreme conditions.

Limitations and Challenges

Liquid Silicone Rubber

1.High Initial Tooling Cost: Molds for injection molding can be expensive, making it less suitable for small batch or prototyping.

2.Material Cost: LSR materials tend to be more expensive than traditional silicone.

3.Processing Complexity: Requires specialized equipment and expertise.

Traditional Silicone

1.Lower Precision:

Not suitable for applications demanding intricate features.2.Longer Production Times:

Hand-molding or casting processes are less efficient.3.Less Suitable for High-Temperature or Medical Applications:

Limited thermal stability and biocompatibility.

Choosing the Right Material: Critical Factors

1.Volume of Production:High-volume manufacturing favors LSR due to efficiency and cost per unit.

2.Complexity of Design:Intricate geometries are better suited for LSR injection molding.

3.Application Environment:Medical, aerospace, or food contact applications require high purity and biocompatibility, favoring LSR.

4.Budget Constraints:Small batch or prototyping projects may benefit from traditional silicone.

5.Surface Finish and Transparency Requirements: LSR offers superior aesthetics and clarity.

Future Trends in Silicone Materials

Innovations in Biocompatible LSRs are expanding the scope of medical devices.

Sustainable and Eco-Friendly Silicone Alternatives are emerging, emphasizing recyclability and lower environmental impact.

Advanced Manufacturing Techniques, such as 3D printing with silicone, are on the rise, blending the benefits of both materials.

Enhanced Thermal and Electrical Properties are driving new applications across industries.

Conclusion: Making an Informed Choice

The decision between liquid silicone rubber and traditional silicone hinges on specific project requirements, production scale, and application demands. LSR's advantages in precision, speed, and durability make it the material of choice for high-volume, high-performance applications, particularly in medical, automotive, and electronics sectors. Conversely, traditional silicone remains an accessible, versatile solution for prototyping, sealing, and low-volume projects.

By understanding the distinct properties, processing methods, and application suitability of each, manufacturers and designers can optimize their product development strategies, ensuring performance, cost-efficiency, and long-term reliability.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883