How Silicone Rubber Parts Manufacturing Is Revolutionizing Medical Surgical Instruments

How Custom Silicone Parts Are Revolutionizing Surgical Instruments

Introduction

In the rapidly evolving landscape of medical technology, the integration of custom silicone parts into surgical instruments is ushering in a new era of precision, safety, and efficiency. Silicone, renowned for its biocompatibility, flexibility, and durability, is increasingly becoming a fundamental material in the design and manufacturing of advanced surgical tools. As healthcare providers seek innovative solutions to improve patient outcomes and surgeon performance, custom silicone components offer tailored functionalities that were previously unattainable with traditional materials.

This comprehensive exploration delves into how and why custom silicone parts are revolutionizing the manufacturing of surgical instruments, providing unmatched benefits that elevate the standards of modern healthcare. From design flexibility to sterilization compatibility, we analyze the technological advancements and industry trends that position silicone as the material of choice for next-generation surgical devices.

The Strategic Advantages of Custom Silicone in Surgical Instruments

Unparalleled Biocompatibility and Safety

Silicone is clinically proven to be non-toxic, hypoallergenic, and biocompatible, making it ideal for implantable devices and instrument components that come into direct contact with human tissue. The customization of silicone parts allows manufacturers to tailor material properties to meet specific safety standards and regulatory requirements, ensuring patient safety and compliance.

Enhanced Sterilization Compatibility

Silicone withstands various sterilization methods such as autoclaving, ETO gas, and gamma irradiation without degrading. This compatibility facilitates safe reuse and hygienic standards, crucial for infection control in modern hospitals.

Innovations in Custom Silicone Design for Surgical Instruments

Tailored Shore Hardness for Precise Performance

Custom silicone formulations allow for precise control over shore hardness, enabling manufacturers to produce soft, flexible grips or firm, supportive components as required. This customization enhances tactile feedback and user comfort, critical for delicate surgical procedures.

Complex Geometries and Micro-Features

Advanced molding techniques such as micro-molding and multi-material integration permit the creation of intricate silicone geometries. This capability ensures perfect fit for specific device models, integrated seals, and precise valve components that improve instrument functionality.

Color Coding and Branding

Custom silicone parts can be colored to facilitate instrument identification, tracking, and brand differentiation. This visual enhancement streamlines workflow and reduces errors during surgical procedures.

Key Applications of Custom Silicone Parts in Surgical Instruments

Seals and Gaskets for Fluid Control

Silicone seals and gaskets are vital in minimizing leaks and preventing contamination in surgical devices such as laparoscopic tools, endoscopes, and fluid delivery systems. Their customizable properties ensure perfect sealing under varying pressures.

Ergonomic Handles and Grips

Silicone is used extensively to manufacture ergonomic handles that reduce fatigue and maximize grip stability for surgeons. Custom molded grips improve precision during long procedures.

Insulation and Electrical Components

In electrosurgical instruments, silicone insulation sleeves provide electrical safety and heat resistance. Custom silicone parts ensure reliable insulation tailored to specific device configurations.

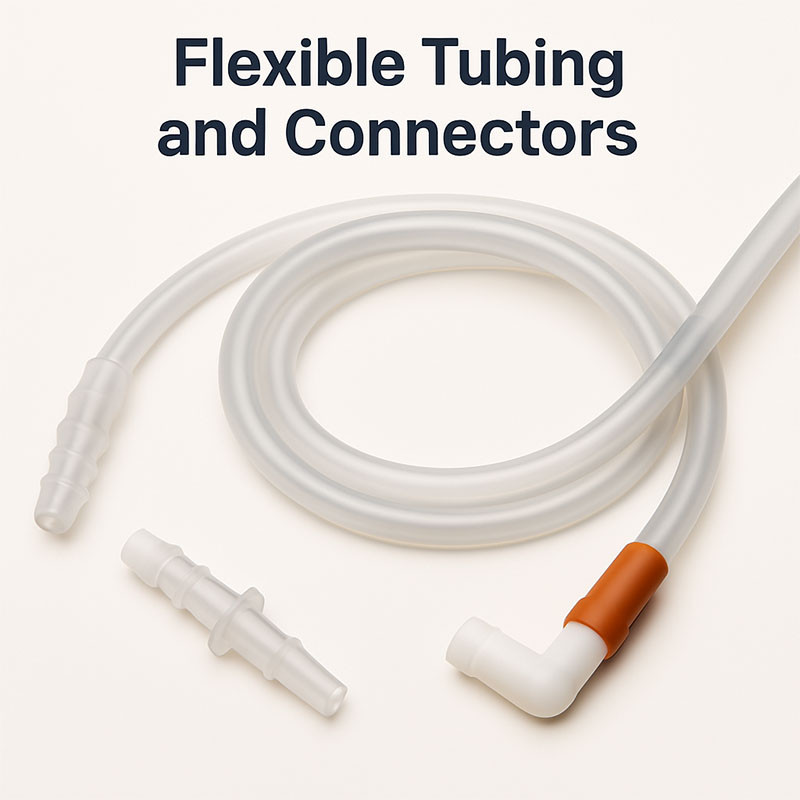

Flexible Tubing and Connectors

Custom silicone tubing offers flexibility and chemical resistance for fluid transfer, venting, and aspiration functions. The ability to produce complex internal geometries enhances flow efficiency.

Manufacturing Processes for Custom Silicone Surgical Components

Injection Molding

Injection molding remains the most common method for producing precise silicone parts. It allows for high-volume production of complex geometries with consistent quality. Custom molds are designed to meet specific device specifications.

Micro-Molding

Micro-molding enables the fabrication of tiny, detailed features essential for miniaturized surgical components. This process is ideal for micro-seals, valves, and sensor housings.

Liquid Silicone Rubber (LSR) Casting

LSR casting offers rapid prototyping and small batch production of custom silicone parts. It is especially useful during product development and clinical testing phases.

Multi-Material Molding

Combining silicone with other materials such as thermoplastics or metals in multi-material molds produces composite components that combine flexibility with rigidity, expanding design possibilities.

Quality Assurance and Regulatory Compliance

Stringent Testing Protocols

Custom silicone parts undergo rigorous testing for biocompatibility (ISO 10993), mechanical properties, thermal stability, and chemical resistance. These tests ensure compliance with medical standards and regulatory bodies like FDA and CE.

Traceability and Documentation

Manufacturers maintain comprehensive records for each batch, ensuring traceability from raw material sourcing to final assembly. This transparency is vital for regulatory audits and recall management.

Future Trends and Innovations in Silicone Medical Components

Smart Silicone Components with Embedded Sensors

Emerging technologies aim to embed sensors within silicone parts for real-time monitoring of device performance, temperature, or biological signals. This integration enhances diagnostic capabilities and patient safety.

Antimicrobial Silicone Surfaces

Developing antimicrobial coatings or additives within custom silicone parts offers additional infection control, especially critical in sterile surgical environments.

3D Printing of Silicone Components

Advances in silicone 3D printing facilitate rapid prototyping and customization at reduced costs, enabling personalized surgical instruments tailored to individual patient needs.

Conclusion

Custom silicone parts are fundamentally transforming surgical instrument design and manufacturing. Their biocompatibility, flexibility, durability, and adaptability enable innovative device features that enhance surgical precision, reduce complications, and improve patient outcomes. As technological advancements continue to unfold, the role of custom silicone components will only expand, cementing their position as integral elements in the future of medical device innovation.

| Application | Material Benefits | Key Features | Typical Devices |

|---|---|---|---|

| Seals & Gaskets | Chemical & Temperature Resistance | Leak-proof, Durable | Endoscopes, Fluid Systems |

| Handles & Grips | Ergonomics & Comfort | Soft, Non-slip | Surgical Forceps, Scalpels |

| Insulation Components | Electrical Safety | Heat & Electrical Resistance | Electrosurgical Devices |

| Tubing & Connectors | Flexibility & Chemical Compatibility | Complex Geometries | Aspiration, Venting Systems |

In summary, the integration of custom silicone parts into surgical instruments represents a paradigm shift in medical device engineering. Their versatility and performance advantages empower manufacturers and healthcare providers to develop safer, more efficient, and highly specialized surgical tools that meet the demanding standards of modern medicine.