How to Choose the Right Medical LSR Partner for Your Business

How to Choose the Right Medical LSR Partner for Your Business

Selecting the optimal medical liquid silicone rubber (LSR) partner is a critical decision that can significantly influence the success, quality, and reliability of your healthcare products. In an industry where precision, compliance, and durability are paramount, partnering with a manufacturer that aligns with your business goals and regulatory requirements is essential. This comprehensive guide provides an in-depth analysis of the key factors, evaluation criteria, and strategic considerations necessary to make an informed choice, ensuring your enterprise gains a competitive edge in the rapidly evolving medical device market.

Understanding the Significance of Medical Liquid Silicone Rubber (LSR) in Healthcare

Medical LSR is renowned for its exceptional biocompatibility, flexibility, chemical stability, and high-performance properties that make it indispensable for a variety of medical applications. From catheter components and infusion sets to implantable devices and wearable sensors, the use of high-quality LSR ensures safety, comfort, and longevity of medical devices.

Critical Criteria for Selecting a Medical LSR Partner

1. Proven Industry Experience and Technical Expertise

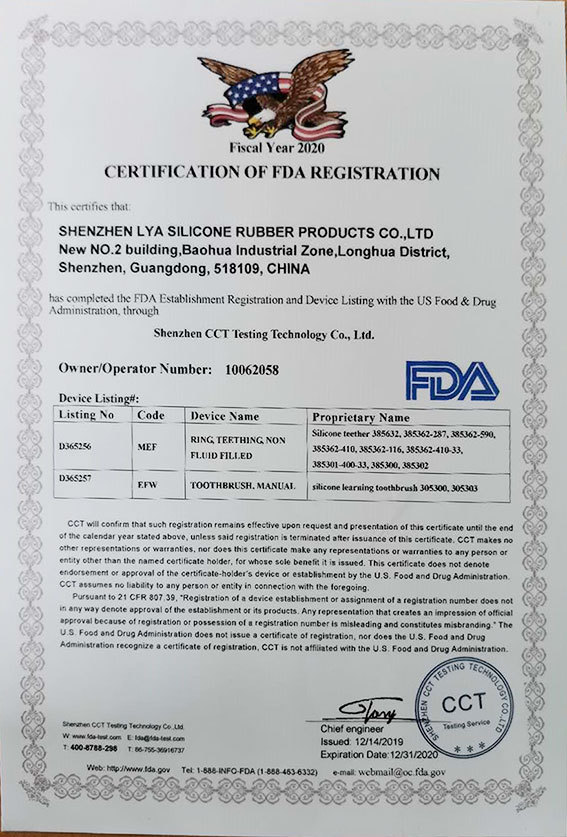

An established LSR manufacturer with extensive experience in the medical sector is better equipped to navigate the complexities of medical-grade materials. Look for partners with a strong track record in producing certified and compliant silicone products, demonstrating deep understanding of medical standards such as ISO 13485, FDA regulations, and EU MDR.

2. Quality Assurance and Regulatory Compliance

Quality assurance (QA) is non-negotiable in medical manufacturing. Your partner must have comprehensive QA systems in place, including raw material testing, in-process inspections, and final product verification. Ensure they possess certifications such as ISO 13485, ISO 9001, and CE marking to guarantee adherence to international standards.

3. Advanced Manufacturing Capabilities and Innovation

State-of-the-art production facilities with cleanroom environments and precision molding technology are vital. The ability to customize formulations, scale production efficiently, and incorporate innovative features can give your products a competitive advantage.

4. Custom Formulation and Material Development

The ideal partner offers bespoke silicone formulations tailored to your specific application needs, whether it involves enhanced transparency, specific durometer ranges, or advanced sterilization compatibility. Their R&D team should be capable of collaborative development to optimize product performance.

5. Supply Chain Stability and Scalability

A reliable supply chain ensures timely delivery and inventory management that match your production schedules. The partner must demonstrate scalability to meet growing demand without compromising quality.

6. Cost Efficiency and Transparent Pricing

While quality is paramount, cost competitiveness is also critical. Transparent pricing models, minimal hidden fees, and flexible payment terms help maintain budget control throughout product development and manufacturing.

7. Customer Support and Technical Service

A dedicated technical support team that offers training, troubleshooting, and after-sales service fosters a long-term partnership. Their responsiveness and expertise can resolve issues promptly, minimizing delays.

In-Depth Evaluation: How to Assess Potential LSR Partners:

| Evaluation Criteria | Key Questions to Ask | Indicators of Excellence |

Experience & Reputation | How long have you been serving the medical industry? | Decades of proven success, references, case studies |

| Quality Certifications | Are your facilities certified to international standards? | ISO 13485, FDA registration, CE marking |

| Technical Capabilities | Can you customize formulations? | Advanced R&D, flexible manufacturing processes |

Regulatory Support | Do you assist with documentation for approvals? | Expertise in documentation, testing reports |

Production Capacity | What is your maximum output per month? | Ability to scale with customer needs |

Lead Time & Delivery | What are your typical lead times? | Consistent, reliable delivery schedules |

| Cost Structure | How transparent are your pricing models? | No hidden costs, competitive rates

|

Key Considerations for Building a Successful Partnership

1.Aligning Business Goals and Compliance Standards

Ensure your partner's business philosophy aligns with your quality and compliance standards. Transparent communication about regulatory responsibilities and quality expectations is vital.

2.Evaluating Material Consistency and Reliability

Request sample batches and conduct rigorous testing to verify material consistency, biocompatibility, and performance. Consistent quality in raw materials translates directly into reliable end products.

3.Assessing Technological Innovation and Customization

Your partner should demonstrate innovative capabilities, such as formulation enhancements for improved sterilization resistance or biocompatibility. Their R&D team should be proactive in developing new solutions aligned with medical advancements.

4.Understanding Lead Times and Supply Chain Resilience

Discuss production schedules, inventory management, and contingency plans. A resilient supply chain mitigates risks associated with material shortages or disruptions.

5.Evaluating Post-Sales Support and Collaboration

A responsive customer service team with technical expertise ensures ongoing support, troubleshooting, and product optimization, fostering long-term collaboration.

Conclusion: Making an Informed Choice for Long-Term Success

The decision to partner with a medical LSR manufacturer should be driven by comprehensive evaluation and strategic alignment. By meticulously analyzing experience, quality standards, technological capabilities, and supply chain robustness, your business can forge a trustworthy partnership that accelerates product innovation, ensures regulatory compliance, and ultimately delivers superior healthcare solutions.

Investing time and resources into selecting the right partner is an investment in product excellence, patient safety, and market competitiveness. A trusted medical LSR partner is not just a supplier but a collaborative partner dedicated to your long-term growth and success in the healthcare industry.

About Us: Your Trusted Medical Silicone Partner

We specialize in providing high-quality, customizable medical liquid silicone rubber solutions tailored to meet the strictest industry standards. With decades of experience, cutting-edge manufacturing facilities, and a dedicated team of regulatory experts and R&D professionals, we are committed to supporting your innovation journey and ensuring your medical devices' success.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883