Innovations in Liquid Silicone Rubber (LSR) for Healthcare Devices

Innovations in Liquid Silicone Rubber (LSR) for Healthcare Devices

Introduction: Revolutionizing Medical Devices with Liquid Silicone Rubber (LSR)

The healthcare industry is experiencing a transformative wave driven by innovative materials and manufacturing technologies, with Liquid Silicone Rubber (LSR) at the forefront. Known for its superior biocompatibility, flexibility, and durability, LSR has become a cornerstone in designing next-generation medical devices. As we delve into the latest advancements, it becomes evident that LSR’s evolving landscape offers unprecedented opportunities to improve patient outcomes, device performance, and manufacturing efficiency.

Understanding Liquid Silicone Rubber (LSR): The Foundation of Medical Innovation

Liquid Silicone Rubber (LSR) is a two-component, high-purity silicone elastomer that is processed via injection molding. Its unique properties include excellent thermal stability, chemical resistance, and biocompatibility—making it ideal for implantable devices, wearable sensors, and diagnostic equipment.

Key Attributes of LSR in Healthcare Applications

- Biocompatibility: Meets ISO 10993 standards, ensuring safety for long-term contact with human tissue.

- Transparency: Facilitates visual inspection of internal components.

- Flexibility & Softness: Mimics natural tissue, providing comfort and efficacy.

- Chemical & Temperature Resistance: Endures sterilization processes without degradation.

- Moldability & Precision: Enables complex geometries and tight tolerances.

Cutting-Edge Innovations in LSR for Healthcare Devices

1. Advanced Formulations Enhancing Biocompatibility and Functionality

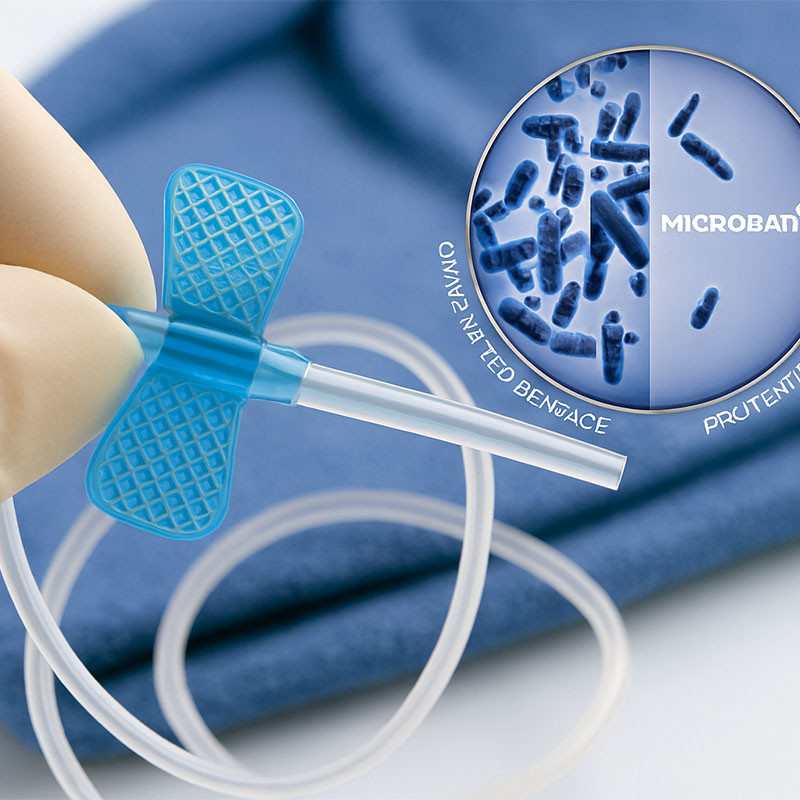

Recent breakthroughs involve customized LSR formulations that optimize biocompatibility for specific medical applications. These formulations incorporate innovative additives such as antimicrobial agents and anti-fouling compounds to reduce infection risks and prevent biofilm formation.

Low-Temperature Cure LSR

Development of low-temperature curing LSR allows for faster manufacturing cycles and reduced energy consumption, which is crucial for large-scale production of disposable medical consumables.

2. Precision Manufacturing Techniques for Complex Geometries

Injection molding remains the primary manufacturing process for LSR, but innovations in mold design and process control have expanded its capabilities.

Multi-Shot and Overmolding Technologies

The multi-shot injection molding process enables the integration of multiple materials within a single device, such as soft and hard silicone components. This is particularly advantageous for sensor housings and drug delivery systems, where precision integration of different functionalities** is required.

Microfabrication and Ultra-Precise Molding

Advances in microfabrication allow for ultra-fine features—such as microchannels and nanostructures—to be reliably produced in LSR. These innovations are critical for biosensors and microfluidic devices, enhancing sensitivity and performance.

3. Integration of Smart Technologies with LSR Components

The convergence of flexible electronics with LSR-based substrates has led to smart healthcare devices capable of real-time monitoring.

Embedded Sensors and Conductive LSR

Development of conductive LSR composites enables integrated sensors for temperature, pressure, and biochemical detection. These sensors are flexible, durable, and biocompatible, making them ideal for wearables and implantables.

Wireless Connectivity and Data Transmission

Embedding wireless modules within LSR housing facilitates remote patient monitoring, telemedicine, and personalized healthcare, revolutionizing patient engagement and clinical workflows.

4. Sustainable and Eco-Friendly LSR Solutions

Environmental considerations are increasingly influencing material development.

Bio-Based and Recyclable LSR

Innovative research focuses on bio-based silicone formulations derived from renewable resources, offering sustainable alternatives to traditional petroleum-based LSR. These materials retain performance characteristics while reducing environmental impact.

Sterilization-Friendly and Recyclable Materials

Formulations that withstand multiple sterilization cycles and are recyclable contribute to sustainable manufacturing practices in medical device industries.

Future Trends and Emerging Technologies in LSR for Healthcare

- Nanotechnology Integration: Embedding nanomaterials for enhanced antimicrobial properties and sensor sensitivity.

- Smart LSR with Embedded Electronics: Fully integrated biosensing platforms for personalized treatment.

- Enhanced Sterilization Compatibility: Developing LSR formulations compatible with advanced sterilization techniques like ethylene oxide and gamma irradiation.

Conclusion: The Future of Liquid Silicone Rubber in Healthcare

The continuous evolution of LSR technology is poised to redefine healthcare device design and manufacturing. From antimicrobial formulations to microfabrication and smart integrations, innovation in liquid silicone rubber is central to creating more effective, safer, and sustainable medical devices. As research and development accelerate, medical professionals and device manufacturers will benefit from tailored, high-performance silicone solutions that meet the rigorous demands of modern healthcare.

References

- Industry reports on medical-grade silicone materials

- ISO 10993 standards for biocompatibility

- Recent publications on antimicrobial silicone formulations

- Case studies on microfabrication in LSR

- Innovations in smart healthcare devices using LSR