Precision and Purity: A Deep Dive into Optical LSR Injection Molding for High-Performance Applications

Why Optical LSR is Replacing Glass and Plastic in Modern Manufacturing

For decades, glass seemed to be the ultimate material for optical applications, valued for its transparency and heat resistance. However, the rise of technologies like high-output LEDs has highlighted its limitations, such as weight and fragility. This has paved the way for Optical Liquid Silicone Rubber (LSR), a high-purity, thermoset material that is revolutionizing the production of optical components through precision injection molding. Unlike traditional thermoplastics such as Polycarbonate (PC) and Acrylic (PMMA) that can yellow or degrade over time with UV and heat exposure, Optical LSR maintains its clarity and mechanical stability. This unique combination of durability and optical performance makes it an increasingly popular choice for everything from automotive lighting to advanced medical devices.

The Unmatched Clarity and Purity of Optical Grade LSR

Optical LSR's chemical structure, based on silicon and oxygen, gives it a clarity that rivals even the best glass, with some grades achieving light transmission rates of over 94%. This exceptional transparency across both visible and UV spectrums ensures minimal light loss, which is critical for the efficiency of LED lighting systems and other sensitive optical devices. A key advantage is its resistance to yellowing, a common issue with plastics when exposed to heat or UV light, ensuring long-term performance and aesthetic appeal.

Superior Durability and Flexibility

While glass is brittle and prone to breaking, Optical LSR offers remarkable flexibility and impact resistance. This doesn't mean it's overly soft; optical grades typically have a durometer of around 70 Shore A, providing a firm structure that can withstand significant vibration and physical impact without cracking. This resilience makes it ideal for demanding environments, such as automotive lenses and outdoor lighting fixtures that are exposed to rough conditions. The material is also inherently scratch-resistant, further preserving its optical properties over its service life.

Thermal and Environmental Stability

One of the most significant advantages of Optical LSR is its exceptional thermal stability. It can perform consistently at temperatures up to 150°C (302°F), a crucial feature for components placed near high-output LEDs, which generate considerable heat. This stability, combined with its resistance to UV radiation and various chemicals, makes Optical LSR perfect for outdoor, automotive, and sterile medical applications where other materials might fail.

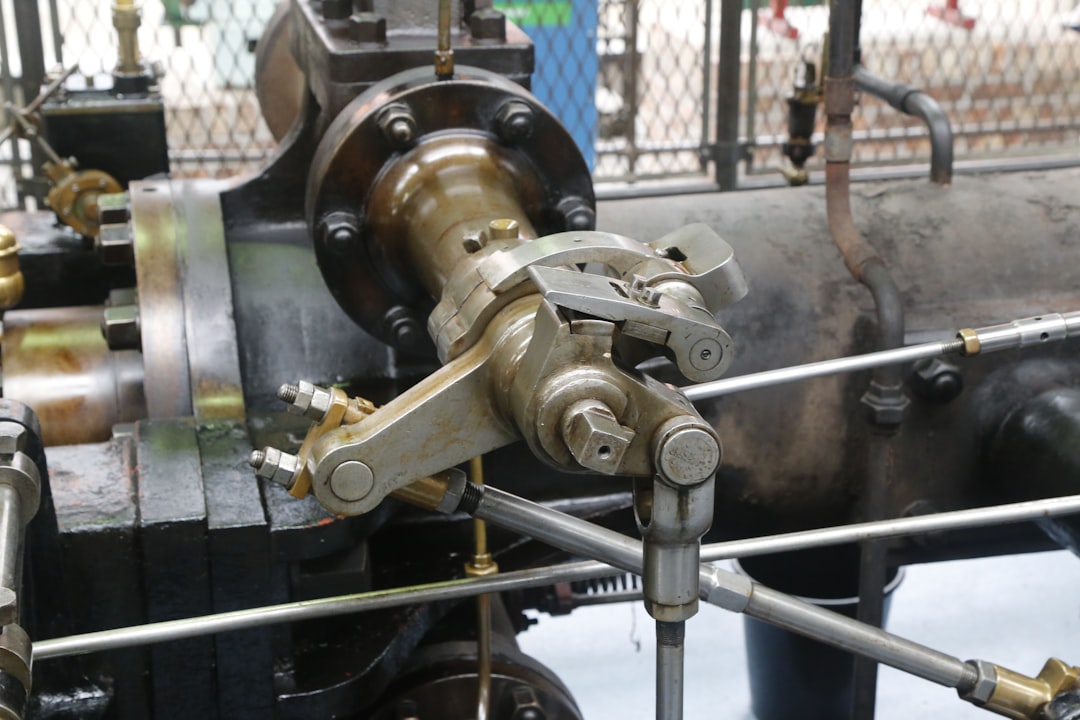

The LSR Injection Molding Process: A Symphony of Precision

Liquid Silicone Rubber injection molding is a highly controlled manufacturing process tailored to the unique properties of this thermoset material. Unlike thermoplastic molding, it involves injecting the two-part liquid material into a heated mold, where it cures and solidifies.

The Two-Component System

Optical LSR typically consists of two liquid components, 'A' and 'B', which are pumped from separate containers. These components are precisely mixed in a static mixer, often along with any desired color pigments, before being injected into the mold. This automated mixing process ensures a perfectly homogeneous material, which is critical for consistent optical quality and mechanical performance.

Curing Inside the Mold

The mold is heated to temperatures between 160°C and 200°C. When the low-viscosity LSR enters the hot cavity, its viscosity initially drops further, allowing it to perfectly replicate intricate surface details of the mold—a key factor for producing high-precision lenses. The heat then triggers a rapid curing (vulcanization) process, hardening the material into its final, solid shape. This entire cycle is incredibly efficient, often taking as little as 30 seconds.

Mold Design and Part Ejection

Because Optical LSR flawlessly reproduces the mold surface, the finish of the mold itself is paramount. A highly polished, SPI-A2 grade surface is often required to achieve a glass-like finish on the final part without any secondary polishing. Due to the material's flexibility, ejector pins, common in thermoplastic molding, are not used as they could damage the part. Instead, parts are often removed manually or with robotic assistance.

Design Freedom: Pushing the Boundaries of Optical Components

LSR injection molding provides designers with extraordinary freedom compared to traditional manufacturing methods.

Complex Geometries and Micro Features

The material’s very low viscosity allows it to fill extremely thin sections and tiny, complex voids within a mold. This enables the creation of micro-features, intricate lens arrays, and freeform optical surfaces that would be difficult or impossible to produce with other materials. Designers can integrate multiple elements, such as a lens and a seal, into a single component, reducing part counts, simplifying assembly, and lowering costs.

Overcoming Traditional Molding Limitations

Optical LSR's flexibility allows for the design of parts with undercuts and even negative draft angles without the need for complex and costly side-actions in the mold. Furthermore, LSR cools without significant sink marks or internal stresses, even in parts with varying wall thicknesses from as thin as 0.25 mm to as thick as 50 mm. This dimensional stability is crucial for ensuring the accuracy and performance of optical lenses.

| Feature | Optical LSR | Polycarbonate (PC) | Glass |

|---|---|---|---|

| Light Transmission | Up to 94% | 88-90% | Up to 95% |

| Thermal Stability | Up to 150°C | Lower, can deform | Very High |

| UV Resistance | Excellent, non-yellowing | Poor, yellows without additives | Excellent |

| Impact Resistance | Excellent, flexible | Good | Poor, brittle |

| Design Flexibility | High (thin walls, undercuts) | Moderate | Low |

| Weight | Low | Low | High |

Key Applications Driving the Growth of Optical LSR

The unique properties of Optical LSR make it the ideal material for a growing number of advanced applications. The global market for optical grade LSR is expanding rapidly, a trend driven by its adoption in high-tech industries.

Advanced Automotive Lighting

In the automotive sector, Optical LSR is used to create durable, lightweight, and complex lenses, light guides, and display components. Its ability to withstand high temperatures from LEDs and resist environmental factors makes it perfect for headlamps, taillights, and interior ambient lighting systems.

High-Performance LED Lighting

For general and industrial lighting, LSR is used to mold lenses and optics that efficiently direct and focus light from high-power LEDs. Its thermal stability prevents degradation, ensuring a long and reliable service life for luminaires used in demanding indoor and outdoor environments.

Medical and Healthcare Devices

Biocompatibility and sterilization resistance make LSR suitable for medical devices, including components for endoscopes and surgical lighting. Its clarity is essential for diagnostic and imaging equipment where precision is paramount.

Addressing Challenges in LSR Injection Molding

While the process is highly advanced, it comes with its own set of challenges that require expertise and careful control.

Flash Prevention

Due to LSR's extremely low viscosity, there's a tendency for the material to seep into the parting lines of the mold, creating a thin, unwanted layer known as flash. This requires exceptionally precise mold construction and careful design of parting lines and venting to minimize or eliminate flash on optically critical surfaces.

Process Control

Achieving consistent part quality depends on the strict control of process parameters like mold temperature, injection pressure, and material mixing ratios. Automated systems are crucial for maintaining the narrow process window required for defect-free optical parts.

The Future is Clear

Optical Liquid Silicone Rubber injection molding represents a significant leap forward in the manufacturing of high-performance optical components. Its superior combination of optical clarity, durability, and design flexibility allows it to outperform glass and conventional plastics in a wide array of demanding applications. As industries continue to push the boundaries of technology, the demand for stronger, lighter, and more complex optical parts will only grow, cementing Optical LSR's role as a key enabling material for the innovations of tomorrow.