Silicone Medical Products in Cosmetic and Reconstructive Surgery

Silicone Medical Products in Cosmetic and Reconstructive Surgery

Introduction: Transforming Patient Outcomes with Advanced Silicone Medical Products

In the rapidly evolving landscape of cosmetic and reconstructive surgery, silicone medical products have established themselves as the gold standard for durability, biocompatibility, and aesthetic excellence. As pioneers in the development of medical-grade silicone, we are committed to providing innovative solutions that meet the highest standards of safety, functionality, and natural appearance. This comprehensive exploration delves into the state-of-the-art silicone implants, biocompatible materials, and cutting-edge techniques that are revolutionizing patient care.

The Evolution of Silicone in Medical Applications

Silicone has a storied history in medicine, dating back over five decades, owing to its unique physical properties and biological inertness. Initially used in catheter manufacturing and wound dressings, silicone's transition into aesthetic and reconstructive surgery marked a significant milestone. Its resilience to degradation, flexibility, and minimal tissue reactivity have made it the material of choice for implantable devices.

Modern silicone products are manufactured under strict ISO standards, ensuring sterility, purity, and consistency. Advances in silicone chemistry have enabled the development of highly specialized formulations that mimic the natural tissue feel and appearance, offering superior outcomes for both surgeons and patients.

Types of Silicone Medical Products in Cosmetic and Reconstructive Surgery

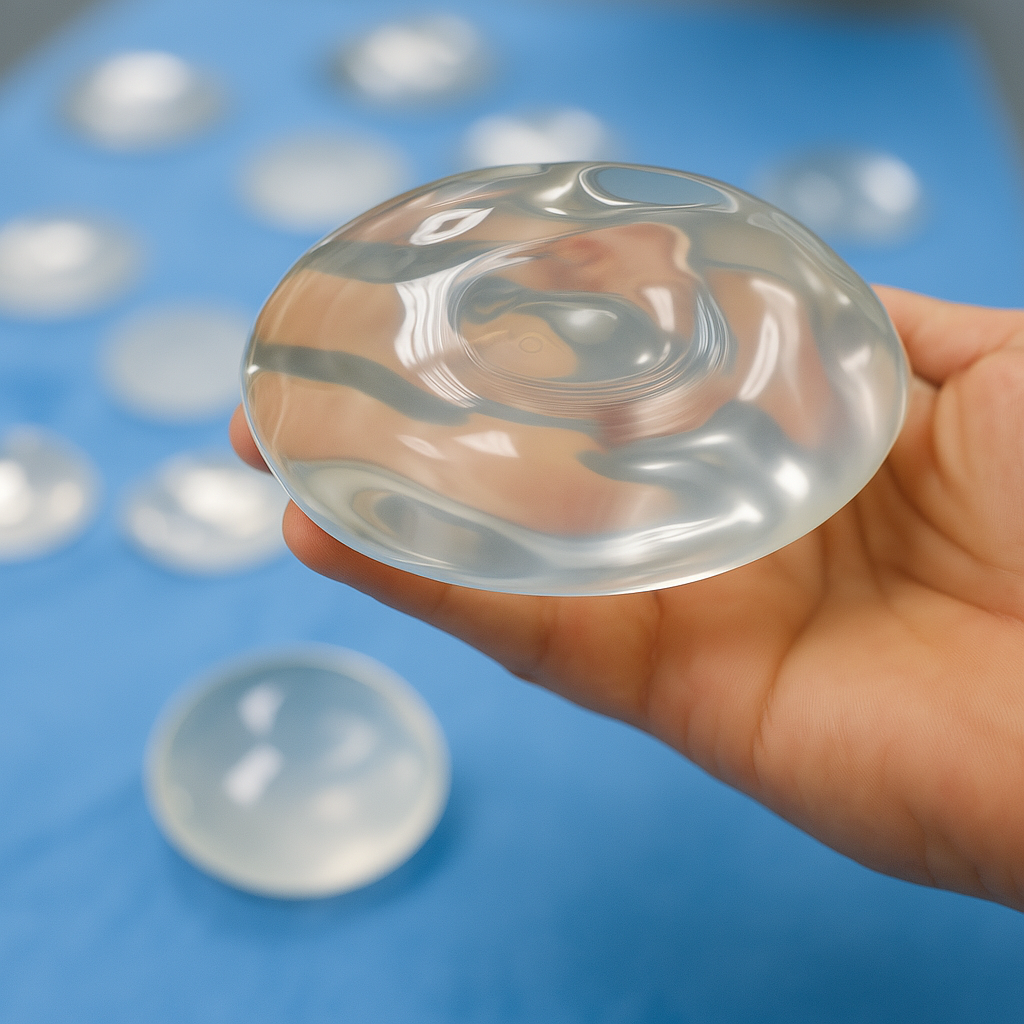

Silicone Breast Implants: The Pinnacle of Aesthetic Enhancement

Silicone breast implants remain the most popular choice for augmentation and reconstruction, thanks to their natural feel and appearance. These implants are composed of a medical-grade silicone shell filled with cohesive silicone gel, which maintains its shape and minimizes leakage risk.

Key Features:

- Highly cohesive gel for safety and durability

- Various shapes and profiles for tailored aesthetic results

- Textured or smooth shells to influence tissue integration and implant stability

- Range of sizes to suit individual patient anatomy

Silicone Facial Implants and Prosthetics: Restoring and Enhancing Facial Features

Facial reconstructive procedures utilize silicone implants to correct trauma, congenital deformities, or age-related volume loss. These implants are crafted to mimic natural facial contours, offering long-lasting results.

Common applications include:

- Chin and jawline augmentation

- Nasal implants for rhinoplasty

- Cheek and orbital rim reconstructions

Silicone prosthetics are also extensively used in auricular, nasal, or ocular prosthetics, providing lifelike appearance and functional restoration.

Silicone Wound Dressings and Soft Tissue Fillers

Beyond implants, medical-grade silicone is employed in wound management devices, promoting scar minimization and skin regeneration. Additionally, soft tissue fillers made from silicone derivatives are utilized for minimally invasive aesthetic procedures.

Features include:

- Silicone gel sheets for scar reduction

- Injectable silicone-based fillers for wrinkle and fold correction

- Biocompatibility and low reactivity minimize adverse reactions

Biocompatibility and Safety of Silicone Medical Products

Biocompatibility is paramount in implantable silicone devices. Medical-grade silicones undergo rigorous testing to ensure they are non-toxic, non-carcinogenic, and resistant to microbial colonization.

Key considerations include:

- Low inflammatory response post-implantation

- Minimal capsular contracture risk in breast augmentation

- Ease of surgical placement and removal if necessary

- Long-term stability with minimal degradation

Advancements in silicone surface modifications have further reduced complications such as implant malposition and rippling, ensuring patient safety and satisfaction.

Innovations in Silicone Manufacturing and Design

Recent innovations have propelled silicone medical products into new realms of performance and customization:

- Cohesive gel formulations that retain shape even if ruptured, enhancing safety profiles

- Textured surfaces that promote tissue adhesion and reduce implant rotation

- Pre-shaped implants designed with anatomical accuracy for specific body regions

- 3D imaging and printing technologies for personalized implant designs

Manufacturers now leverage nanotechnology and surface coating techniques to minimize biofilm formation and improve tissue integration.

Surgical Techniques and Best Practices for Silicone Implant Placement

Successful outcomes with silicone medical products depend heavily on surgical expertise and appropriate technique selection:

Incision Placement and Implant Pocket Creation

- Submuscular or subglandular placement in breast surgery

- Preauricular or intraoral incisions for facial implants

- Minimal invasive approaches to reduce scarring and recovery time

Handling and Insertion of Silicone Implants

- Use of specialized surgical tools to prevent rupture

- Gentle tissue dissection to accommodate implant size and shape

- Secure fixation to prevent migration

Postoperative Care and Monitoring

- Regular imaging assessments to detect early complications

- Patient education on activity restrictions

- Management of capsular contracture or other adverse events through medical or surgical intervention

Advantages of Silicone Medical Products in Surgical Outcomes

| Feature | Benefit |

|---|---|

| Natural Feel and Appearance | Achieves highly realistic aesthetic results, boosting patient satisfaction |

| Durability and Longevity | Implants often last 10-20 years with minimal maintenance |

| Biocompatibility | Reduces the risk of rejection and inflammatory responses |

| Customizability | Wide range of shapes, sizes, and surface textures for tailored outcomes |

| Minimal Maintenance | Low complication rates and ease of revision surgeries if needed |

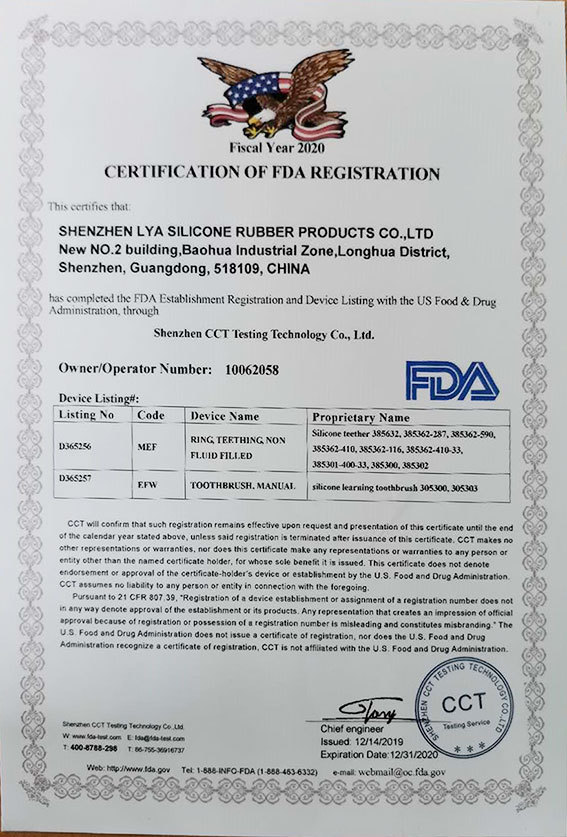

Regulatory Standards and Quality Assurance

Our silicone medical products are manufactured in compliance with FDA regulations, ISO 13485 standards, and CE marking. Rigorous quality control protocols ensure each implant or device meets stringent safety and performance criteria.

Quality assurance measures include:

- Sterilization validation

- Mechanical testing for tensile strength and tear resistance

- Biocompatibility testing per ISO 10993 standards

- Traceability and documentation for each batch

Future Trends and Developments in Silicone Medical Products

The future of silicone in cosmetic and reconstructive surgery is poised for remarkable advancements, driven by biotechnology and material science:

- Smart silicone implants with sensor integration for real-time monitoring

- Bioactive silicone surfaces promoting tissue regeneration

- Nanostructured silicones to further reduce complications

- Regenerative approaches combining silicone scaffolds with stem cell therapies

Conclusion: Elevating Surgical Excellence with Silicone Medical Products

Silicone medical products continue to set the benchmark in cosmetic and reconstructive surgery, offering unparalleled versatility, safety, and aesthetic outcomes. As the technology landscape advances, surgeons and patients alike benefit from innovative, high-performance silicone solutions that transform lives and restore confidence.

In summary, the integration of cutting-edge silicone technology into cosmetic and reconstructive surgery signifies a paradigm shift towards more natural, durable, and safe patient outcomes. Our commitment to innovation and excellence ensures that silicone medical products remain at the forefront of medical advancements in this vital field.