The Ultimate Guide to Medical Grade Silicone for Beginners

Introduction to Medical Grade Silicone: The Essential Material in Healthcare

Medical grade silicone has revolutionized the healthcare industry, offering unmatched versatility, safety, and durability. As a high-performance biomaterial, it is extensively used in medical devices, implants, prosthetics, and wound care products. For beginners venturing into the realm of medical-grade materials, understanding the fundamentals of silicone is crucial for making informed decisions, whether you're a manufacturer, healthcare professional, or researcher.

This comprehensive guide aims to provide an in-depth overview of medical grade silicone (MGS), covering its properties, manufacturing processes, safety standards, applications, and key considerations for selecting the right silicone for medical purposes.

What is Medical Grade Silicone? An In-Depth Explanation

Medical grade silicone is a specialized silicone material that meets stringent regulatory standards for biocompatibility, purity, and safety. Unlike industrial silicone, which may contain additives or impurities unsuitable for prolonged contact with human tissue, medical grade silicone is specifically formulated to ensure non-toxicity, minimal allergic reactions, and long-term stability.

Key characteristics include:

1.High biocompatibility: It does not cause adverse tissue reactions.

2.Chemical inertness: Resistant to bodily fluids and sterilization processes.

3.Flexibility and elasticity: Mimics natural tissue movement.

4.Thermal stability: Operates efficiently across a wide temperature range.

5.Durability: Maintains performance over extended periods.

Regulatory Standards and Certifications for Medical Grade Silicone

Ensuring compliance with regulatory standards is vital when selecting or manufacturing medical grade silicone.

Key standards include:

1.ISO 10993: Biological evaluation of medical devices, focusing on biocompatibility.

2.USP Class VI: Demonstrates biocompatibility and safety for implantable and contact devices.

3.FDA Regulations: In the United States, FDA approval or clearance is mandatory for silicone used in medical devices. Manufacturers must provide comprehensive documentation including certificates of analysis, safety data sheets, and biocompatibility test reports to validate their silicone's suitability for medical applications.

Properties of Medical Grade Silicone That Make It Ideal for Medical Use

Medical grade silicone possesses a unique combination of properties that make it the material of choice for various medical applications:

| Property | Description | Importance in Medical Applications |

Biocompatibility | Non-toxic, hypoallergenic | Reduces risk of adverse reactions |

Chemical Resistance | Resistant to bodily fluids, sterilants | Ensures longevity and safety |

Thermal Stability | Operates across -50°C to +250°C | Suitable for autoclaving and sterilization |

Flexibility & Elasticity | Soft, stretchable | Mimics tissue, comfortable implants |

| Transparency | Clear or opaque options | Enables visual inspection in devices |

| Durability | Maintains properties over time | Ideal for long-term implants |

Common Applications of Medical Grade Silicone in Healthcare

Medical grade silicone is a versatile material with a broad spectrum of applications, including but not limited to:

1. Medical Implants and Prosthetics

Silicone implants such as breast implants, facial prosthetics, and testicular prostheses are favored for their biocompatibility, natural feel, and longevity. These implants are designed to withstand body movements and sterilization cycles without degrading.

2. Wound Care and Management Products

Silicone-based scar sheets, gels, and dressings are widely used to reduce scarring and promote healing. Their soft, conformable nature ensures gentle contact with sensitive skin, while their non-reactive properties prevent irritation.

3. Catheters and Tubing

Silicone's flexibility and chemical resistance make it ideal for catheters, feeding tubes, and IV lines, which require long-term placement and sterilization.

4. Medical Devices and Equipment

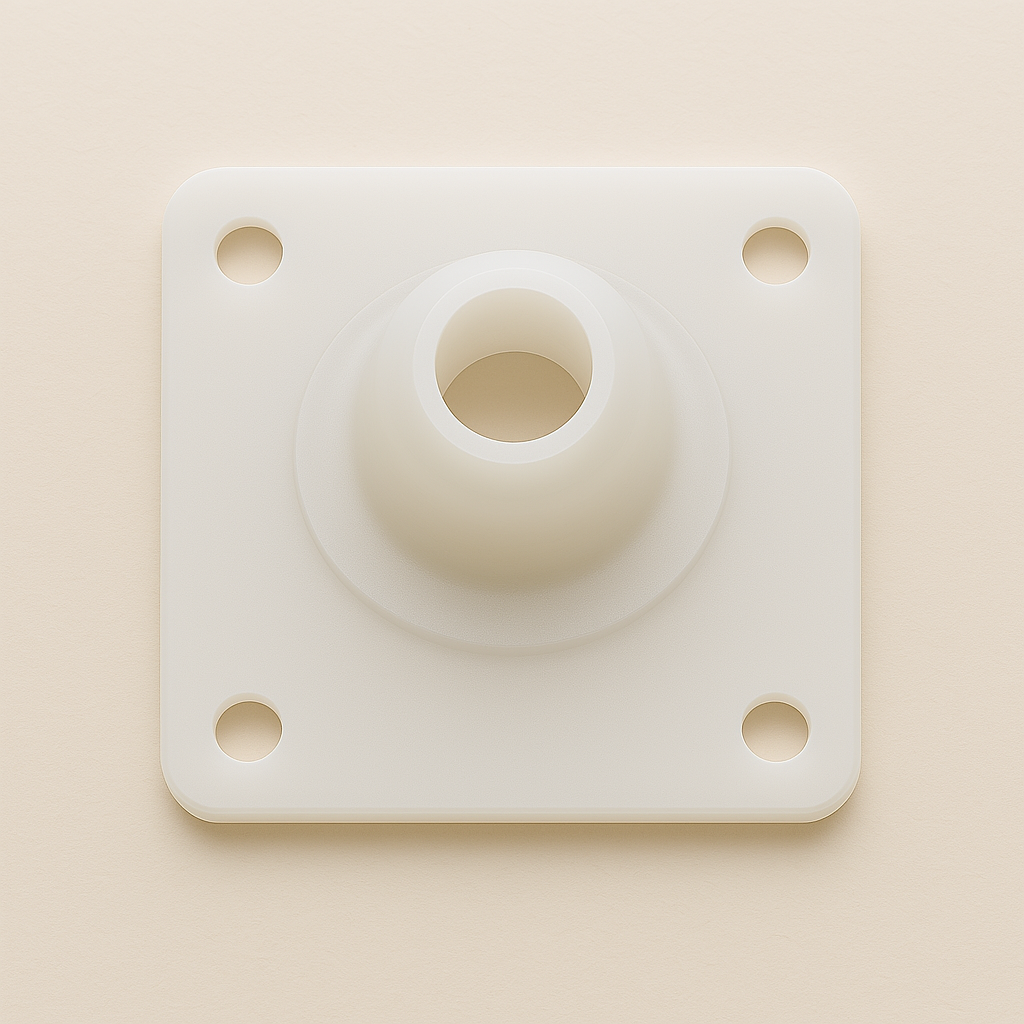

Components such as gaskets, seals, and membranes in various diagnostic and therapeutic devices leverage silicone's resistance to high temperatures and bodily fluids.

5. Dental and Orthopedic Applications

Silicone impression materials and orthopedic padding benefit from its elasticity and biocompatibility, providing accurate impressions and comfortable cushioning.

Key Factors to Consider When Choosing Medical Grade Silicone

Selecting the appropriate silicone for medical applications involves assessing multiple factors:

a. Purity and Certification

Ensure the silicone meets all relevant standards (ISO 10993, USP Class VI, FDA approval). Verify certificates of analysis and biocompatibility test results.

b. Mechanical Properties

Match the flexibility, tensile strength, and elongation properties** to the specific application requirements**.

c. Sterilization Compatibility

Confirm that the silicone can withstand autoclaving, gamma irradiation, or ethylene oxide sterilization without degradation.

d. Transparency and Coloration

Depending on the application, opt for clear or pigmented silicone to facilitate visual inspection or meet aesthetic needs.

e. Compatibility with Other Materials

Assess the adhesion and interaction with other materials used in device assembly or implants.

Handling and Processing of Medical Grade Silicone

Proper handling and processing are critical to maintain the integrity and safety of medical grade silicone:

1.Cleanroom environment: To prevent contamination during manufacturing.

2.Sterilization methods: Autoclaving, ethylene oxide, or gamma radiation, depending on the silicone type.

3.Molding techniques: Injection molding, compression molding, or extrusion, tailored to application specifics.

4.Post-processing: Polishing, trimming, and inspection to ensure defect-free products.

Safety and Biocompatibility Testing for Medical Silicone

Before deploying silicone in medical applications, comprehensive biocompatibility testing must be conducted, including:

1.Cytotoxicity Tests: To verify cell compatibility.

2.Sensitization and Irritation Tests: To assess allergic responses.

3.Intracutaneous Reactivity: To evaluate skin reactions.

4.Implantation Studies: To observe tissue response over time.

5.Chemical Analysis: To detect residual catalysts or impurities.

Only silicone that passes these rigorous tests and adheres to regulatory standards is suitable for medical use.

Future Trends and Innovations in Medical Grade Silicone

The evolution of medical grade silicone continues to focus on enhanced biocompatibility, functional integration, and sustainability:

1.Smart Silicone Materials: Incorporating bioactive agents or sensor capabilities for real-time health monitoring.

2.Enhanced Sterilization Resistance: Developing formulations that withstand multiple sterilization cycles without compromising performance.

3.Eco-friendly Manufacturing: Reducing environmental impact through green chemistry approaches.

4.Customized Solutions: Employing 3D printing technologies for patient-specific implants and devices.

Conclusion: The Indispensable Role of Medical Grade Silicone in Modern Healthcare

Medical grade silicone stands as a cornerstone biomaterial that combines safety, flexibility, and durability. Its broad spectrum of applications and superior properties make it an indispensable choice for a myriad of medical devices and implants. As technology advances, the development of innovative silicone formulations promises even greater functionality, safety, and patient comfort.

For manufacturers, healthcare providers, and researchers, understanding the intricacies of medical grade silicone is essential to harness its full potential and deliver superior healthcare solutions. By choosing certified, high-quality silicone, stakeholders ensure patient safety, device efficacy, and long-term success in medical innovations.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883