The Unseen Hero: How Silicone Parts Manufacturers Are Revolutionizing Medical and Healthcare Applications

Introduction: The Indispensable Role of Medical-Grade Silicone

In the intricate and demanding world of healthcare, the materials used are as critical as the medical procedures themselves. Among a host of options, medical-grade silicone has emerged as a true cornerstone material, utilized in a vast array of applications from single-use consumables to long-term implantable devices. Its prevalence is no accident; silicone possesses a unique combination of properties that make it exceptionally suited for medical use. Manufacturers of silicone parts are the unsung heroes, translating material science into tangible products that enhance patient care, improve safety, and drive medical technology forward.

What Makes Silicone "Medical-Grade"?

Not all silicone is created equal. The term "medical-grade" signifies that the material has been rigorously tested and certified to meet stringent quality and safety standards for healthcare applications. This classification, often referred to as Class VI, means the silicone has undergone testing for biocompatibility, ensuring it won't cause adverse reactions when in contact with the human body. These materials are produced in controlled environments to ensure high purity and eliminate contaminants, a crucial factor for any medical application.

Biocompatibility: The Foremost Advantage in Healthcare

Biocompatibility is the primary reason silicone is a material of choice in the medical field. It refers to the material's ability to coexist with bodily tissues and fluids without causing harm, immune responses, or allergic reactions. Unlike materials such as latex, medical-grade silicone is hypoallergenic and gentle on the body, making it safe for both short-term skin contact and long-term implantation.

The Pillars of Performance: Key Properties of Medical Silicone

Beyond biocompatibility, several other properties make silicone invaluable for medical device manufacturers.

- Durability and Flexibility: Silicone maintains its mechanical integrity, elasticity, and shape over time, even under stress. This is vital for applications like prosthetic liners and joint implants.

- Temperature Resistance: It can withstand a wide range of temperatures without degrading or becoming brittle, making it suitable for devices that require sterilization or are used in extreme temperature procedures.

- Chemical Inertness: Silicone is resistant to chemicals, biofluids, and cleaning agents, ensuring the longevity and reliability of medical devices.

- Sterilizability: Medical silicone parts can be repeatedly sterilized using various methods (steam, ETO gas) without losing their physical properties, a critical requirement for reducing infection risks in clinical settings.

Liquid Silicone Rubber (LSR) vs. High-Consistency Rubber (HCR)

Silicone parts manufacturers primarily use two forms of the material: Liquid Silicone Rubber (LSR) and High-Consistency Rubber (HCR).

| Feature | Liquid Silicone Rubber (LSR) | High-Consistency Rubber (HCR) |

|---|---|---|

| Form | Two-part liquid system | Solid, gum-like sheets |

| Processing | Injection molding | Extrusion, compression molding |

| Curing | Platinum-catalyzed (addition cure) | Peroxide-catalyzed |

| Best For | High-volume, complex, precision parts | Tubing, extruded profiles |

LSR injection molding is particularly favored for producing intricate medical components with high precision and repeatability, such as seals, gaskets, and parts for wearable devices.

Life-Saving Applications: Silicone in Medical Implants

Silicone's bio-durability and compatibility make it a trusted material for devices implanted within the human body. These range from short-term to long-term applications.

- Cardiovascular Devices: Silicone is used to insulate pacemaker leads and in the construction of artificial heart valves.

- Prosthetics and Reconstruction: It is commonly used in breast implants, joint prosthetics (for hands and feet), and maxillofacial prosthetics, offering a natural feel and appearance.

- Drug Delivery Systems: Implantable devices that provide a controlled release of medication often utilize silicone components.

- Cochlear Implants and Stents: The flexibility and inertness of silicone are ideal for sensitive applications like cochlear implants and various types of stents.

Enhancing Patient Care: Everyday Medical Devices

Silicone is ubiquitous in a wide range of external and short-term medical products that patients and healthcare professionals rely on daily.

- Respiratory Care: Respiratory masks, nebulizer parts, and sleep apnea masks use silicone to create a soft, comfortable, and airtight seal for effective breathing support.

- Tubing and Catheters: Silicone tubing is preferred for fluid transport, drainage systems, and catheters due to its flexibility, non-reactivity, and ability to withstand sterilization.

- Wound and Scar Management: Silicone gel sheets create a protective barrier that hydrates the skin, helping to soften scars and reduce redness and itching.

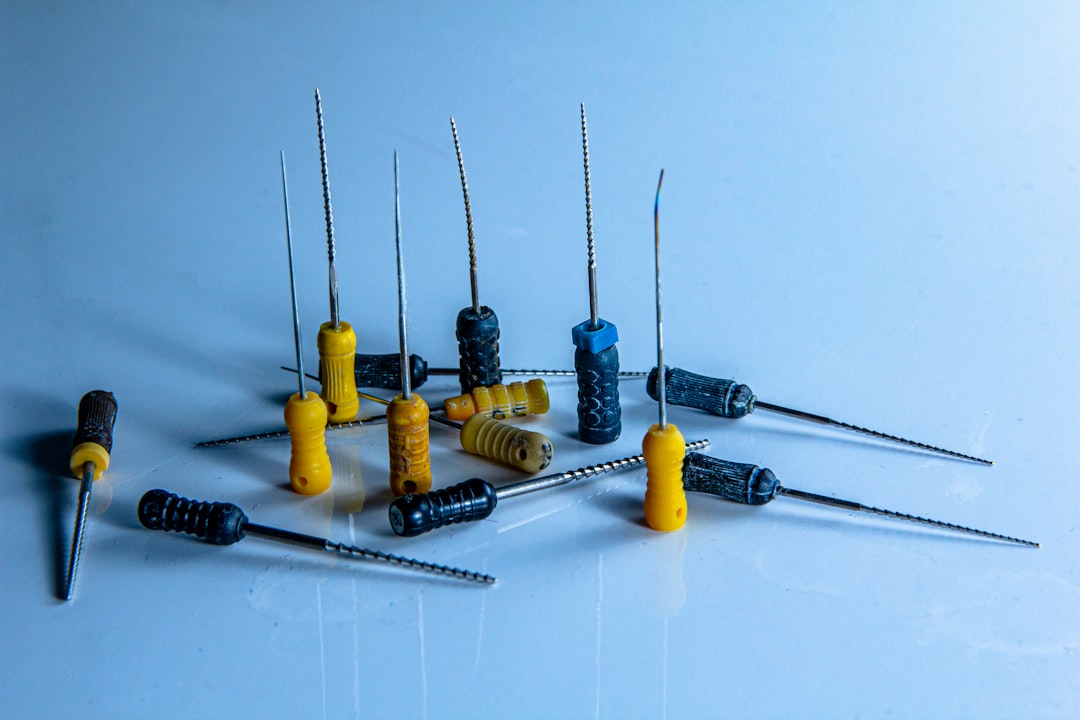

The Manufacturing Edge: Precision Molding and Overmolding

Advanced manufacturing techniques are key to producing high-quality silicone medical parts. Liquid Injection Molding (LIM) allows for the creation of highly complex and flash-less parts at high volumes, which is crucial for disposable items. Furthermore, silicone overmolding—the process of molding silicone onto a metal or plastic substrate—is used to add soft-touch grips to surgical instruments or create integrated seals on device housings, enhancing functionality and user comfort.

A Sterile and Safe Alternative to Latex

For decades, latex was a common material in healthcare, but its potential to cause severe allergic reactions has driven a shift towards alternatives. Medical-grade silicone has emerged as the superior choice, being non-allergenic and providing a safe solution for both patients and healthcare providers.

The Role of a Silicone Parts Manufacturer in Ensuring Quality

A specialized silicone parts manufacturer plays a critical role in the healthcare supply chain. They are not simply producers but expert partners who understand the stringent regulatory landscape, including FDA and ISO standards. Their expertise covers:

- Material Selection: Guiding clients to the correct grade of silicone for their specific application.

- Tooling Design: Creating precise molds for defect-free production.

- Process Control: Implementing controlled manufacturing processes to ensure consistency and quality.

- Validation and Compliance: Ensuring all parts meet the required certifications and biocompatibility standards like USP Class VI and ISO 10993.

The Future of Silicone in Medical Technology

The role of silicone in medicine continues to expand. Innovations in material science are leading to the development of new silicone composites and advanced manufacturing methods like 3D printing. As medical technology moves towards wearable monitoring devices, microfluidics, and personalized medicine, the demand for high-performance, biocompatible silicone components will only grow, cementing the crucial role of expert silicone parts manufacturers in the future of healthcare.