Top Industries Using Liquid Silicone Rubber (LSR) and Why They Love It

Introduction

Liquid Silicone Rubber (LSR) has revolutionized modern manufacturing with its unique blend of flexibility, durability, biocompatibility, and precision. As a high-performance elastomer, LSR's versatility makes it an indispensable material across a broad spectrum of industries. Our comprehensive analysis explores the top industries leveraging LSR, detailing why this material continues to dominate and how it enables manufacturers to push the boundaries of innovation.

Automotive Industry: Enhancing Safety, Comfort, and Performance with LSR

Why the Automotive Sector Relies on LSR

The automotive industry demands materials that can withstand extreme temperatures, resist chemical exposure, and maintain flexibility over prolonged use. Liquid Silicone Rubber excels in these areas, making it a preferred choice for a multitude of automotive components.

Key Applications in Automotive

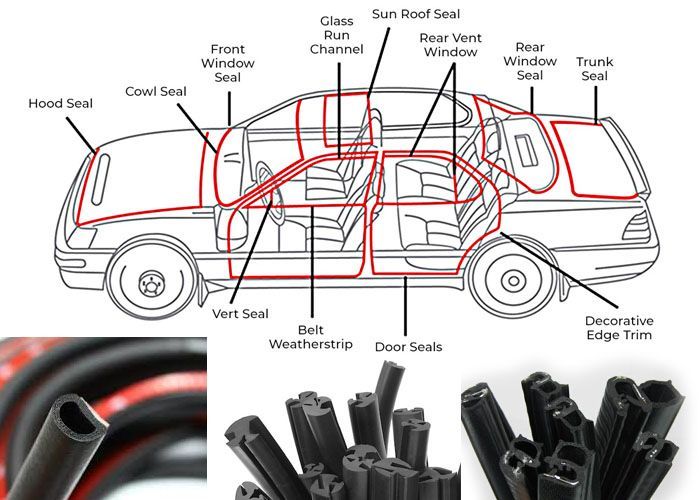

1.Seals and Gaskets:

LSR's superior sealing capabilities prevent leaks of fluids and gases, ensuring vehicle safety and efficiency.2.HVAC Components:

Its thermal stability allows for durable, flexible seals in heating, ventilation, and air conditioning systems.3.Lighting and Electronics:

LSR's transparency and electrical insulation properties are perfect for LED lighting covers and electronic housings.4.Airbag Components:

The elasticity and quick curing of LSR enable the production of precise, reliable airbag covers and inflator seals.Why Automotive Manufacturers Favor LSR

1.Temperature Resilience:

Capable of enduring temperatures from -55°C to +300°C, ensuring long-term performance.2.Chemical Resistance:

Resistant to oils, fuels, and other automotive chemicals, reducing degradation over time.3.Design Flexibility:

Enables complex, precise molds for intricate parts, reducing assembly time and costs.4.Enhanced Safety:

Its biocompatibility and non-toxic nature are critical for safety-related components.

Medical Industry: Prioritizing Biocompatibility and Sterilization Compatibility

The Critical Role of LSR in Medical Devices

In the healthcare sector, biocompatibility, sterilization compatibility, and durability are non-negotiable. Liquid Silicone Rubber's inherent properties meet these rigorous standards, making it an essential material for various medical applications.

Leading Medical Applications

Medical Tubing and Catheters:

LSR's flexibility and chemical inertness make it ideal for minimally invasive procedures.Wearable Medical Devices:

Its skin-safe properties and easy sterilization support continuous patient monitoring equipment.Injection Molding Components:

Precise and sterile production of valves, seals, and diaphragms.Why Medical Manufacturers Depend on LSR

Biocompatibility:

Complies with ISO 10993 standards, ensuring safety for internal and external medical applications.Sterilization Compatibility:

Resists sterilizing agents like ethylene oxide, gamma radiation, and autoclaving without degradation.Non-Toxic and Hypoallergenic:

Suitable for sensitive skin and internal use, reducing allergy risks.High Precision:

Enables manufacturing of micro-scale features critical for medical devices.

Consumer Electronics: Merging Flexibility with Aesthetic Excellence

The Role of LSR in Consumer Electronics

In an industry driven by innovation and aesthetics, Liquid Silicone Rubber provides flexible, durable, and visually appealing solutions for electronic device housings, buttons, and seals.

Key Applications in Consumer Electronics

1.Wearable Devices:

LSR's soft touch and elasticity enhance user comfort for smartwatches and fitness trackers.2.Device Casings and Covers:

Its transparency and colorability allow for sleek, customizable designs.3.Seals and Gaskets:

Protect internal components from dust, moisture, and shocks.4.Keypads and Buttons:

The soft-touch feel improves user experience.Why Brands Choose LSR

Aesthetic Versatility: Easily colored and textured to match brand design.

Impact and Shock Resistance: Protects delicate electronics from drops and vibrations.

Temperature Tolerance: Ensures performance in diverse environmental conditions.

Long-Term Durability: Maintains softness and appearance over extended use.

Home Appliances and Consumer Goods: Improving User Experience and Product Longevity

LSR's Impact in Home Appliances

From kitchen gadgets to personal care devices, LSR's flexibility, resistance to wear, and aesthetic qualities contribute significantly to product innovation.

Prominent Use Cases

Kitchen Appliances: Seals, gaskets, and handles that withstand frequent cleaning and thermal cycling.

Personal Care Devices: Soft-touch grips and protective covers for razors, epilators, and massagers.

Waterproof Components: Ensuring water resistance in devices like smart speakers and IoT gadgets.

Electronics and Semiconductor Industry: Precision, Insulation, and Reliability

Why the Electronics Sector Prefers LSR

Precision manufacturing, thermal management, and electrical insulation are critical in electronics. LSR’s properties address all these needs efficiently.

Core Applications

Microelectronics Encapsulation:

Protects delicate circuits from moisture, dust, and mechanical shocks.Insulating Components:

Excellent dielectric properties make LSR ideal for insulating high-voltage parts.Optical Components:

Its transparency supports light transmission in sensors and displays.Connectors and Switches:

Flexible and resilient, ensuring reliable contact over millions of cycles.Industrial Manufacturing: Improving Efficiency and Sustainability

LSR in Industrial Applications

Manufacturers utilize LSR in automation, sealing, and safety components to optimize production efficiency.

Key Benefits

1.Rapid Curing:

Fast cycle times increase throughput.2.High-Precision Molding:

Facilitates complex geometries with tight tolerances.3.Cost-Effectiveness:

Reduces assembly steps and material waste.4.Environmental Resistance:

Suitable for outdoor and industrial environments.Conclusion

Liquid Silicone Rubber (LSR) has firmly established itself as a game-changing material across multiple industries. Its exceptional properties—thermal stability, chemical resistance, biocompatibility, and design flexibility—make it the material of choice for innovative, durable, and high-performance products. As industries continue to evolve, the demand for LSR’s unique qualities will only grow, fueling further innovations that benefit manufacturers and consumers alike.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883