Why Custom Liquid Silicone Rubber Is Essential for Advanced Medical Devices

Introdction:

In the rapidly evolving landscape of medical technology, the demand for high-performance, reliable, and biocompatible materials has never been greater. Among these materials, custom liquid silicone rubber (LSR) stands out as a cornerstone component for advanced medical devices. Its unique combination of flexibility, chemical stability, and biocompatibility makes it indispensable for a wide spectrum of applications—from implantable devices to diagnostic equipment.

In this comprehensive analysis, we delve into the multifaceted advantages of custom LSR, exploring how tailored formulations and manufacturing processes elevate the performance, safety, and longevity of next-generation medical solutions.

The Critical Role of Customization in Liquid Silicone Rubber for Medical Applications

Customization in liquid silicone rubber is not merely a luxury—it is a necessity in the realm of medical device manufacturing. Off-the-shelf silicone formulations often fail to meet the stringent regulatory, biocompatibility, and functional requirements unique to medical applications.

Custom LSR formulations allow manufacturers to optimize properties such as hardness, elasticity, color, thermal stability, and biocompatibility precisely aligned with the specific demands of each device. This level of tailored engineering ensures that the final product not only complies with medical standards but also surpasses expectations in performance and safety.

Key Benefits of Custom Liquid Silicone Rubber in Medical Devices

| Benefit | Description |

Enhanced Biocompatibility | Custom formulations can incorporate medical-grade additives, ensuring compatibility with human tissue and fluids. |

Optimized Mechanical Properties | Adjusting hardness and elasticity for specific functions like sealing, cushioning, or actuation. |

| Improved Chemical Resistance | Custom LSR resists bodily fluids, sterilization agents, and cleaning chemicals without degradation |

| Superior Thermal Stability | Tailored formulations withstand sterilization processes such as autoclaving or gamma irradiation. |

| Color Customization | For device identification, branding, or aesthetic purposes, with biocompatible pigments. |

Regulatory Compliance | Ensures formulations meet ISO 10993, USP Class VI, and other stringent standards. |

Unmatched Biocompatibility and Safety Standards

Biocompatibility is the cornerstone of any material used in medical devices. Custom liquid silicone rubber is inherently biocompatible, but tailored formulations further enhance safety and efficacy.

Advanced formulations incorporate medical-grade catalysts and crosslinkers to ensure minimal leachables and extractables, reducing the risk of adverse tissue reactions. These custom LSRs are rigorously tested to meet ISO 10993 standards, including cytotoxicity, sensitization, and irritation assessments.

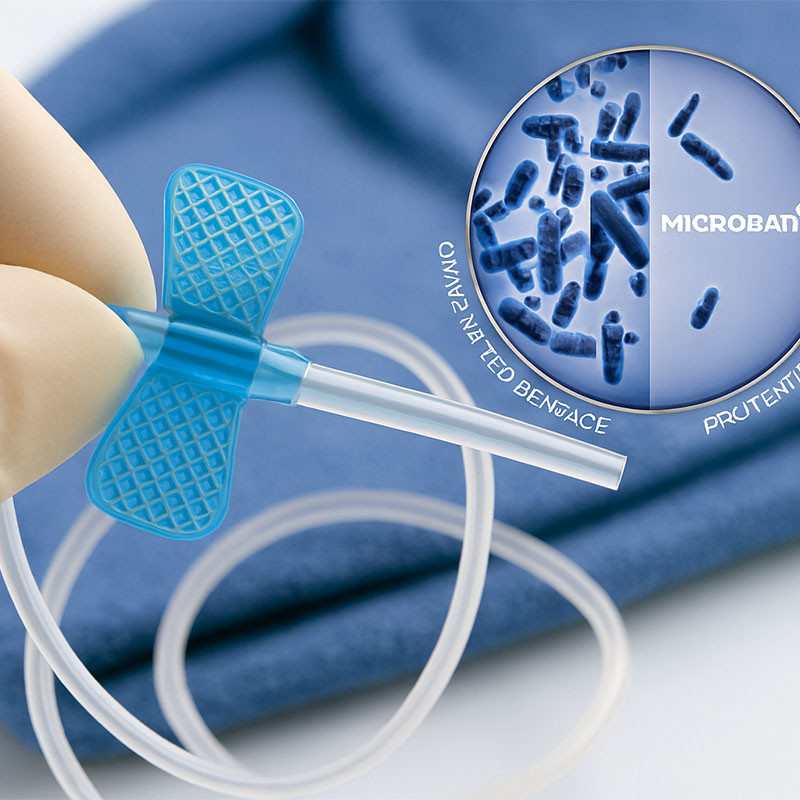

Furthermore, customization enables the integration of antimicrobial properties or drug-eluting capabilities, expanding the functionality of implantable and diagnostic devices. These innovations significantly reduce infection risks and improve patient outcomes.

Superior Mechanical and Physical Properties for Critical Devices

Advanced medical devices demand materials that can withstand harsh environments while maintaining functional integrity. Custom liquid silicone rubber provides exceptional mechanical properties that can be precisely calibrated.

Key Mechanical Attributes:

High Elasticity and Flexibility: Ensures devices can mimic tissue movement and reduce mechanical fatigue.

Tear and Abrasion Resistance: Critical for long-term implants and wearable devices subjected to repetitive stress.

Dimensional Stability: Maintains shape and size during sterilization and usage cycles.

Low Compression Set: Preserves original shape even after prolonged compression, vital for sealing applications.

Thermal and Chemical Resilience:

Custom formulations withstand high-temperature sterilization methods, including autoclaving, EtO, and gamma irradiation, without compromising elasticity or integrity. They also resist common chemicals encountered during cleaning and sterilization, such as hydrogen peroxide, alcohols, and disinfectants.

Design Flexibility and Complex Geometries

Liquid silicone rubber offers excellent processability, enabling the manufacturing of complex geometries and microstructures critical in medical devices.

Custom formulations can be optimized for molding, extrusion, or 3D printing, facilitating rapid prototyping and mass production. This flexibility allows for integrated features like channels, vents, or embedded sensors, enhancing device functionality.

Regulatory Advantages of Custom Liquid Silicone Rubber

In the highly regulated environment of medical device manufacturing, compliance is non-negotiable. Custom LSR formulations are designed to meet or exceed international standards, simplifying the regulatory approval process.

Key regulatory benefits include:

Traceability: Precise formulation control aids in documentation and quality assurance.

Validated Biocompatibility: Tailored formulations undergo rigorous testing aligned with ISO 10993 and USP standards.

Sterilization Compatibility: Formulations are developed with validated sterilization methods in mind, ensuring no adverse effects post-sterilization.

Reduced Risk of Non-Compliance: Customization minimizes variability, ensuring consistent performance and safety.

Applications of Custom Liquid Silicone Rubber in Medical Devices

1. Implantable Devices

Custom LSR's biocompatibility, durability, and flexibility make it ideal for implantable sensors, catheters, prosthetics, and drug delivery systems. Its long-term stability ensures minimal tissue irritation and device longevity.

2. Diagnostic Equipment

From microfluidic channels to sealing components, custom LSR provides precision and reliability. Its resistance to bodily fluids and sterilization processes makes it suitable for point-of-care devices.

Flexible, skin-friendly, and durable, custom LSR is perfect for wearable sensors, patches, and monitoring devices. Its custom color options facilitate branding and user identification.

4. Surgical Instruments and Accessories

Sterilizable, chemical-resistant, and biocompatible, custom LSR is used in surgical seals, gaskets, and tubing, ensuring high performance during critical procedures.

Innovative Manufacturing Techniques for Custom LSR

Manufacturers leverage advanced processing technologies to produce highly specialized custom LSR components:

Injection Molding: Suitable for high-volume production of precision parts.

Compression Molding: Ideal for larger, thicker components.

Additive Manufacturing (3D Printing): Enables rapid prototyping and complex geometries.

Extrusion: For long, continuous profiles like tubing or seals.

Each method benefits from formulation customization, ensuring material consistency and performance tailored to application-specific requirements.

Quality Assurance and Testing of Custom Liquid Silicone Rubber

Rigorous testing protocols are integral to custom LSR development, ensuring compliance, safety, and performance. These include:

Biocompatibility Testing:

Cytotoxicity, sensitization, irritation.Mechanical Testing:

Tensile, tear, compression set.Chemical Analysis:

Leachable and extractable assessments.Sterilization Validation:

Compatibility with sterilization methods.Aging Studies:

Long-term stability under physiological conditions.Traceability and documentation are maintained throughout the manufacturing process, aligning with ISO 13485 and other medical device quality standards.

Conclusion: Elevating Medical Device Performance with Custom Liquid Silicone Rubber

Custom liquid silicone rubber is not just a material choice—it is a strategic enabler of innovation, safety, and reliability in advanced medical devices. Its tailor-made properties ensure that devices meet the rigorous demands of biocompatibility, mechanical resilience, and regulatory compliance.

As the medical technology sector continues to advance rapidly, custom LSR will play an increasingly pivotal role in driving innovation, enhancing patient outcomes, and setting new standards for medical device excellence.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883