Why Silicone Sleeve Manufacturers are Crucial Innovation Partners for Industrial and Automotive Applications

The Unsung Heroes: How Silicone Sleeve Manufacturers Drive Industrial and Automotive Advancement

In the intricate and demanding worlds of industrial manufacturing and automotive engineering, success hinges on the performance and durability of every single component. Amidst the complex machinery and high-performance engines, a seemingly simple product plays a profoundly critical role: the silicone sleeve. These versatile components are the unsung heroes, providing essential protection against extreme temperatures, abrasion, fluids, and electrical interference that could otherwise compromise system integrity and safety.

While end-users may focus on major systems, engineers and procurement managers understand that foundational components are the bedrock of reliability. The choice of a silicone sleeve manufacturer is not a minor detail; it is a strategic decision that impacts product longevity, operational safety, and overall performance. A premier manufacturer does more than just supply a part; they act as an innovation partner, leveraging material science and process expertise to solve complex challenges. This article delves into the critical importance of high-quality silicone sleeves and the immense value that a specialized manufacturer brings to the industrial and automotive sectors.

What Makes Silicone the Material of Choice?

Silicone's dominance in these demanding applications is no accident. Its unique molecular structure gives it a combination of properties that are difficult to find in any other polymer. Understanding these characteristics is key to appreciating why it is so heavily relied upon.

Key properties include:

- Exceptional Temperature Resistance: Silicone can perform reliably in temperatures ranging from -60°C to over 250°C (-76°F to 482°F), with special formulations pushing these limits even further. This makes it ideal for protecting components near engines, exhaust systems, and industrial ovens.

- Excellent Flexibility: Unlike many plastics that become brittle in the cold or soft in the heat, silicone maintains its flexibility across its entire operating temperature range, preventing cracks and ensuring a consistent seal.

- Superior Electrical Insulation: Silicone is an outstanding dielectric material, making it perfect for sleeving on wires and cables to prevent short circuits and ensure signal integrity, a critical factor in today's software-defined vehicles.

- Chemical and Fluid Resistance: It stands up well against a wide array of oils, coolants, solvents, and chemicals, preventing degradation and ensuring long service life in harsh under-hood or factory floor environments.

- Durability and Longevity: Silicone is inherently resistant to UV radiation, ozone, and weathering, which means it won't degrade when exposed to the elements, making it suitable for both internal and external applications.

Core Applications in the Automotive Industry

The modern vehicle is a complex ecosystem of mechanical and electronic systems operating in a high-stress environment. Silicone sleeve manufacturers provide critical solutions that enhance reliability and safety.

- Engine Bay Protection: Sleeves are used to shield everything from spark plug wires and sensor cables to fuel lines and vacuum hoses from the intense radiant heat generated by the engine and exhaust manifold.

- EV and Hybrid Vehicle Systems: The shift to electric vehicles has created new demands. Silicone sleeves are essential for insulating high-voltage battery cables, protecting intricate wiring harnesses for advanced driver-assistance systems (ADAS), and managing thermal runaway risks in battery packs.

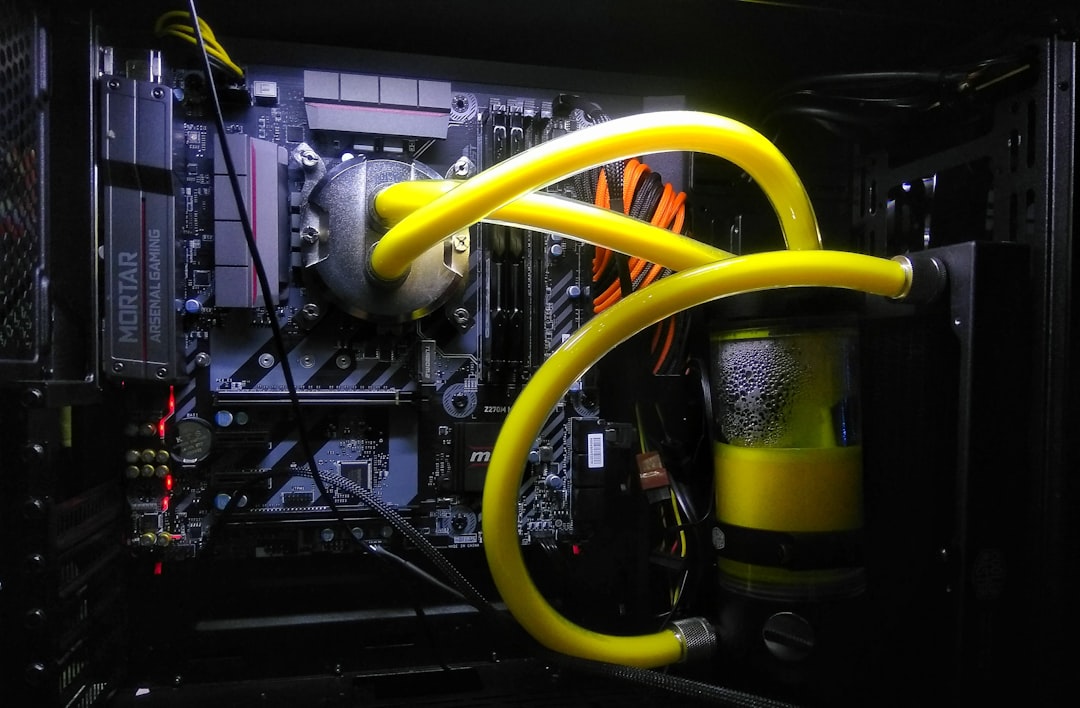

- Fluid Transfer Systems: In turbochargers and cooling systems, silicone hoses and sleeves are used to transport hot air and coolant without degrading, ensuring the engine operates at its optimal temperature.

- Noise, Vibration, and Harshness (NVH): Softer durometer silicone sleeves can be used to dampen vibrations in cables and small lines, contributing to a quieter and more comfortable ride.

Indispensable Uses in Industrial Settings

Industrial environments present their own unique set of challenges, from heavy machinery and robotic automation to chemical processing and high-temperature manufacturing.

- Robotics and Automation: In automated factories, robotic arms contain complex bundles of wires and pneumatic lines that are in constant motion. Braided silicone sleeves protect these bundles from abrasion, flexing fatigue, and contact with industrial fluids.

- Heavy Machinery: Equipment used in mining, construction, and agriculture relies on hydraulic systems. Silicone sleeves protect hydraulic hoses from external abrasion, welding splatter, and high ambient temperatures, preventing costly failures and downtime.

- Food and Beverage Processing: For applications requiring food-grade materials, manufacturers can produce FDA-compliant silicone sleeves that protect wiring and tubing on processing and packaging equipment without risk of contamination.

- Aerospace Wiring: In aerospace, bundles of critical wiring for avionics and control systems are protected with high-performance silicone sleeves that offer fire resistance, a key safety requirement.

The Manufacturing Process: A Mark of Quality

Producing a reliable silicone sleeve is a multi-step process that demands precision and expertise. A top-tier manufacturer controls every variable to ensure consistency and performance.

- Compounding: The process begins with raw silicone polymer, which is mixed with various additives. These can include pigments for color-coding, stabilizers for even greater heat resistance, and fillers to enhance physical strength.

- Extrusion: The compounded material is then fed into an extruder. It is heated and forced through a die, which shapes the material into the continuous profile of a sleeve. The precision of this die is critical for maintaining tight dimensional tolerances.

- Curing: The extruded sleeve immediately enters a curing oven. This process, known as vulcanization, cross-links the polymer chains, giving the silicone its final strength, elasticity, and thermal stability. The time and temperature must be perfectly controlled for optimal properties.

- Post-Curing: Many high-performance applications require a post-curing step, where the sleeves are baked for several hours to remove any residual byproducts from the curing process and further stabilize the material.

- Finishing and Coating: Sleeves can be cut to specific lengths, printed with identifying marks, or treated with specialized coatings. A common enhancement is a braided fiberglass jacket coated with silicone rubber, which dramatically increases abrasion and flame resistance.

Differentiating a Premier Manufacturer from a Mere Supplier

In a global market, many companies can supply silicone sleeves, but only a few can be considered true manufacturing partners. The difference lies in their capabilities, quality systems, and service.

| Feature | Standard Supplier | Premier Manufacturer |

|---|---|---|

| Material Expertise | Offers standard compounds. | Provides custom compounding for specific application needs (e.g., extreme low temperature, specific fluid resistance). |

| Quality Control | Basic dimensional checks. | Rigorous testing for tensile strength, elongation, dielectric strength, and heat aging. Full traceability from raw material to finished product. |

| Certifications | May lack formal certifications. | Holds key industry certifications like IATF 16949 (Automotive), AS9100 (Aerospace), and ISO 9001. |

| Customization | Limited to standard sizes and colors. | Offers full customization of ID, wall thickness, color, printing, and specialized coatings. Provides engineering support for new designs. |

| Technical Support | Basic customer service. | Provides in-depth technical support, failure analysis, and collaborative problem-solving. Acts as a consultant. |

The Importance of IATF 16949 Certification in Automotive Supply

For any component manufacturer in the automotive supply chain, IATF 16949 is the gold standard. It is not just another quality management system; it is a framework for continuous improvement, defect prevention, and the reduction of variation and waste. When a silicone sleeve manufacturer is IATF 16949 certified, it signifies:

- Robust Production Processes: They have proven their ability to produce parts consistently to exacting specifications.

- Risk Management: They proactively identify and mitigate risks throughout their design and manufacturing processes.

- Full Traceability: They can trace a specific batch of sleeves back to the raw materials used, which is crucial for root cause analysis in the event of a field failure.

- Commitment to Quality: It demonstrates a deep-seated organizational commitment to meeting the stringent demands of automotive OEMs.

Innovations in Silicone Sleeve Technology

The field is not static. Leading manufacturers are constantly innovating to meet the challenges of next-generation industrial and automotive design.

- Self-Fusing Sleeves: Tapes and sleeves that, when stretched and wrapped, fuse to themselves to create a seamless, solid insulating barrier without any adhesive.

- Reflective Coatings: Sleeves with aluminized or other reflective outer layers that can reflect over 90% of radiant heat, providing protection for components located just millimeters from hot surfaces.

- Fire-Resistant Sleeves (Pyrojacket): These are constructed with a thick fiberglass braid and a heavy coating of iron oxide silicone rubber. They are designed to withstand continuous exposure to molten splash and direct flame for short periods, protecting critical hoses and cables long enough for a system shutdown.

- EMI/RFI Shielding Sleeves: With the proliferation of electronics, protecting signals from electromagnetic or radio frequency interference is vital. Manufacturers are developing sleeves that incorporate conductive materials to provide shielding.

The Cost of Quality vs. The Price of Failure

Procurement decisions are often driven by price. However, in critical applications, the initial cost of a high-quality silicone sleeve from a reputable manufacturer is dwarfed by the potential cost of failure. A degraded wire insulation can lead to a catastrophic short circuit. A burst hydraulic hose on a piece of heavy machinery can result in hazardous fluid leaks and unscheduled downtime costing thousands of dollars per hour. Sourcing from a certified, experienced manufacturer is an investment in reliability and risk mitigation.

How to Choose the Right Silicone Sleeve Manufacturer

Selecting the right partner requires careful evaluation. Look for:

- Deep Technical Expertise: Do they have engineers on staff who can understand your application and recommend the right material and product?

- Proven Track Record: Can they provide case studies or references from within your industry?

- Relevant Certifications: Do they hold the necessary quality certifications like IATF 16949 for automotive or others relevant to your field?

- In-House Capabilities: A manufacturer that controls the entire process from compounding to finishing has better control over quality and lead times.

- Willingness to Customize: The best partners are willing to work with you to develop a unique solution for a unique problem.

Conclusion: Your Strategic Partner in a Demanding World

Silicone sleeves are far more than just protective tubing; they are engineered components that ensure the safety, reliability, and efficiency of the most advanced automotive and industrial systems. The manufacturer you choose is therefore a critical part of your supply chain and a key contributor to your product's success. By prioritizing expertise, quality, and innovation over simple price-per-meter, you are building a more resilient and competitive final product. A top-tier silicone sleeve manufacturer is not just a vendor—they are an essential partner in navigating the challenges of modern engineering.