Home / All / Silicone Products / Industrial Silicone Products / Custom High-Temperature Silicone Parts Precision Silicone Molding Components OEM/ODM Silicone Manufacturing Factory

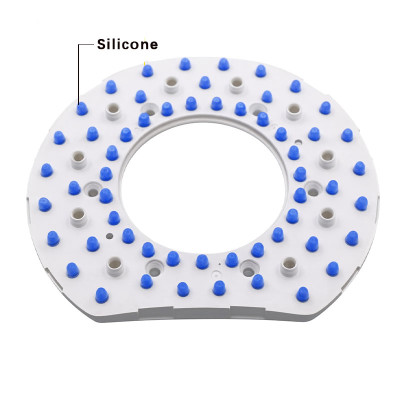

Custom High-Temperature Silicone Parts Precision Silicone Molding Components OEM/ODM Silicone Manufacturing Factory

Detail Information

Product Description

Our Custom High-Temperature Silicone Parts are engineered for manufacturers that require reliable, precision-molded components capable of operating under extreme thermal, mechanical, and environmental conditions. Using premium platinum-cured LSR (Liquid Silicone Rubber) and high-consistency HTV silicone materials, SiliconePlus delivers components that maintain stability from –60°C up to +300°C, ensuring long-term durability even in demanding industrial applications.

Unlike conventional rubber or thermoplastic components, silicone offers superior heat resistance, chemical stability, and elasticity. This makes it ideal for sectors such as automotive, EV battery systems, industrial machinery, medical devices, aerospace, consumer electronics, and high-temperature sealing systems. Our advanced molding capabilities allow us to produce custom geometries—including micro-components, thin membranes, complex seals, valves, insulation parts, and multi-material overmolded structures.

Advanced Silicone Manufacturing Capabilities

✔ LSR Injection Molding

For high-precision, high-volume projects requiring automated production, excellent part consistency, and medical-grade purity.

✔ HTV Compression & Transfer Molding

Suitable for thicker components, large parts, and high-strength structural silicone applications.

✔ Custom Silicone Material Options

Shore A hardness from 10–90

Heat-resistant, flame-retardant, conductive, translucent, or medical-grade formulations

FDA, LFGB, RoHS, REACH compliant materials

✔ Multi-Material Overmolding

Silicone-to-metal, silicone-to-plastic, and 2K overmolding for enhanced bonding and functional integration.

Solving Common B2B Customer Pain Points

1. Dimensional Inconsistency → Precision Mold Control

Our tolerances reach ±0.02 mm, ensuring perfect mating and sealing performance.

2. Poor Heat Aging → High-Temperature Silicone Formula

Parts remain stable and crack-free even under long-term high-heat exposure.

3. Weak Mechanical Strength → Reinforced Silicone Compounds

We provide customized elasticity, tear strength, and tensile performance.

4. Material Odor or Yellowing → Platinum-Cured Silicone Only

No additives, no odor, no contamination—ideal for medical and food-contact applications.

5. Limited Customization → Full OEM/ODM Engineering

Custom molds, colors, hardness, textures, and packaging available.

Why Choose SiliconePlus

✔ 20+ Years of Silicone Manufacturing Expertise

Supporting global automotive, medical, and industrial brands.

✔ End-to-End Engineering Support

From material formulation → mold design → rapid prototyping → mass production.

✔ Advanced Equipment & Automation

Fully automated LSR molding lines ensure repeatability and flawless surface quality.

✔ Global Quality Compliance

All parts meet FDA, LFGB, RoHS, and REACH safety requirements.

✔ Factory-Direct Pricing

Reduce cost and lead time while maintaining premium quality.

✔ Custom Solutions for High-Temperature Applications

We specialize in heat-resistant silicone components for energy, electronics, and EV sectors.

Applications

High-temperature gaskets & seals

Automotive sensor and connector components

Insulation parts for EV battery systems

Medical valves, membranes, and precision micro-parts

Industrial machinery high-heat components

Aerospace and outdoor equipment seals

Related Products

Review

- Loading...

Please send your message to us

- *Mobile Phone

- *Title

- *Content

Contact Person