How to Stay Ahead: Emerging Medical LSR Trends for Future Growth

Introduction:

The Strategic Importance of Liquid Silicone Rubber in Medical Applications

Liquid Silicone Rubber (LSR) is renowned for its exceptional biocompatibility, thermal stability, flexibility, and durability. These attributes make it an ideal choice for a wide spectrum of medical applications, including catheters, implantable devices, prosthetics, and personal protective equipment. The medical industry's increasing demand for safe, reliable, and high-performance materials underscores the critical role of LSR in future healthcare innovations.

Why LSR is the Material of Choice for Medical Devices

1.Biocompatibility:

Meets stringent ISO 10993 standards, ensuring safe contact with human tissue.2.Sterilizability:

Compatible with various sterilization techniques such as EO sterilization, gamma radiation, and steam autoclaving.

3.Chemical Resistance:

Resists bodily fluids, cleaning agents, and pharmaceuticals.

4.Transparency:

Allows for visual inspection in critical applications.

5.Customization:

Easily moldable into complex geometries, supporting innovative device designs.

Emerging Trends in Medical Liquid Silicone Rubber

The future of medical LSR is driven by technological innovation, regulatory shifts, and market demands. Here, we explore the most influential trends that industry stakeholders must monitor and adapt to.

1. Advanced Material Formulations for Enhanced Biocompatibility and Functionality

Recent developments focus on formulating specialized LSR compounds that extend beyond basic biocompatibility. These formulations incorporate antimicrobial agents, anti-fouling properties, and enhanced mechanical strength.

Antimicrobial LSR: Embedding silver nanoparticles or quaternary ammonium compounds to create self-sterilizing surfaces, reducing infection risks.

Anti-fouling LSR: Incorporating hydrophilic coatings to minimize protein adhesion and bacterial colonization on device surfaces.

High-Performance LSR: Improving tear resistance and elasticity for wearable devices subjected to repeated stress.

2. Miniaturization and Precision Manufacturing

As medical devices become increasingly compact and complex, micro-molding and precision injection techniques are revolutionizing LSR applications.

Microfluidic Devices: LSR’s fine detail reproduction enables lab-on-a-chip platforms for diagnostics.

Ultrasmall Components: Manufacturing tiny seals, valves, and connectors with high dimensional accuracy.

3. Integration of Smart Technologies

The convergence of LSR with sensor technology opens new avenues for smart medical devices.

Embedded Sensors: Incorporating biosensors into LSR components for real-time health monitoring.

Conductive LSR: Developing electrically conductive formulations for flexible electrodes and wearable health monitors.

This trend supports the creation of personalized healthcare solutions, emphasizing connectivity and data-driven diagnostics.

4. Sustainable and Eco-Friendly Manufacturing

Environmental considerations are increasingly influencing medical material development.

Bio-based LSR: Sourcing renewable raw materials to reduce carbon footprint.

Recyclable LSR: Innovating reprocessing techniques to enable material recovery without compromising performance.

Regulatory agencies are also emphasizing sustainability, prompting manufacturers to adopt green practices in production.

5. Regulatory Compliance and Certification Advances

The evolving regulatory landscape demands rigorous testing and certification of medical LSR products.

1.Enhanced Biocompatibility Testing: Inclusion of long-term implantation studies.

2.Global Standards Alignment: Meeting FDA, EU MDR, and ISO 13485 requirements.

3.Traceability and Documentation: Implementing digital tracking for raw materials and production batches.

Innovative Applications of Medical LSR

The versatility of liquid silicone rubber continues to expand, driven by technological breakthroughs and clinical needs.

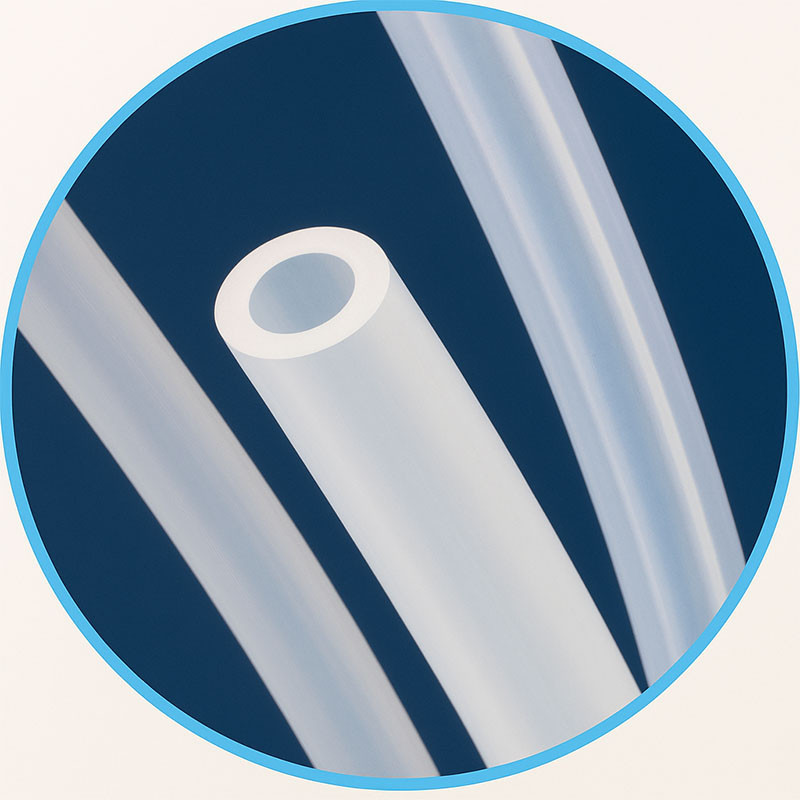

1. Silicone-Based Catheters and Tubing

LSR offers superior flexibility and chemical resistance, making it ideal for catheters used in cardiovascular, urinary, and respiratory systems.

Features: Reduced risk of encrustation, minimized patient discomfort, and enhanced sterilization compatibility.

Emerging Innovations: Development of antimicrobial coatings and radiopaque LSR for easier imaging.

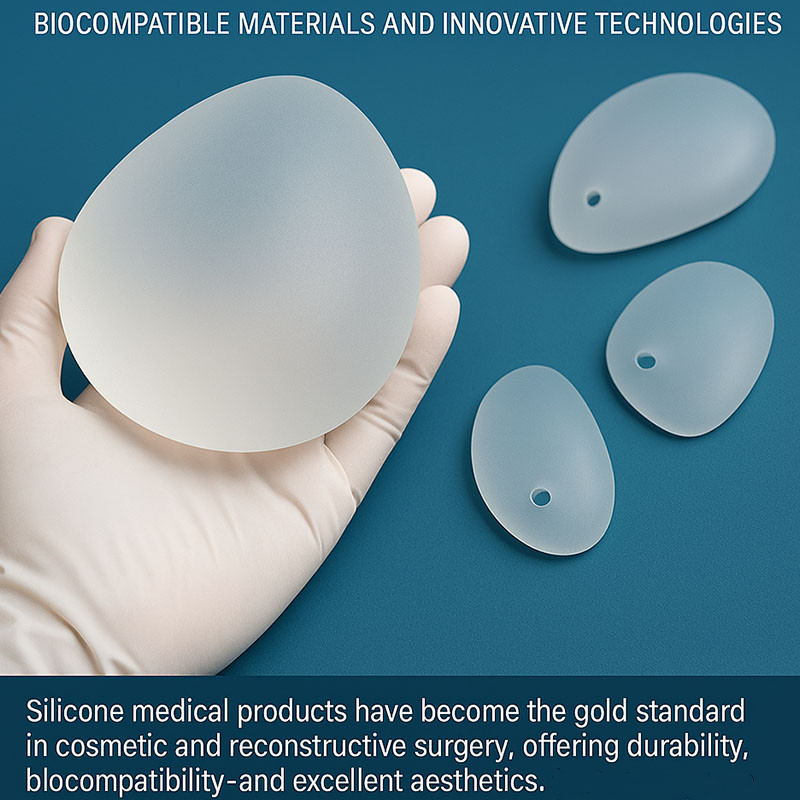

2. Implantable and Prosthetic Devices

The biocompatibility and long-term stability of LSR make it suitable for implantable devices such as ventricular assist devices, cochlear implants, and soft tissue prosthetics.

Design Flexibility: Ability to create complex geometries that conform to human anatomy.

Surface Modifications: Incorporation of drug-eluting layers to prevent infection and promote tissue integration.

3. Wearable Healthcare Devices

The growth of wearable health monitors relies heavily on flexible, lightweight, and durable materials like LSR.

Examples: Fitness trackers, continuous glucose monitors, and smart patches.

Key Attributes: Comfort, robustness, and seamless integration with electronic components.

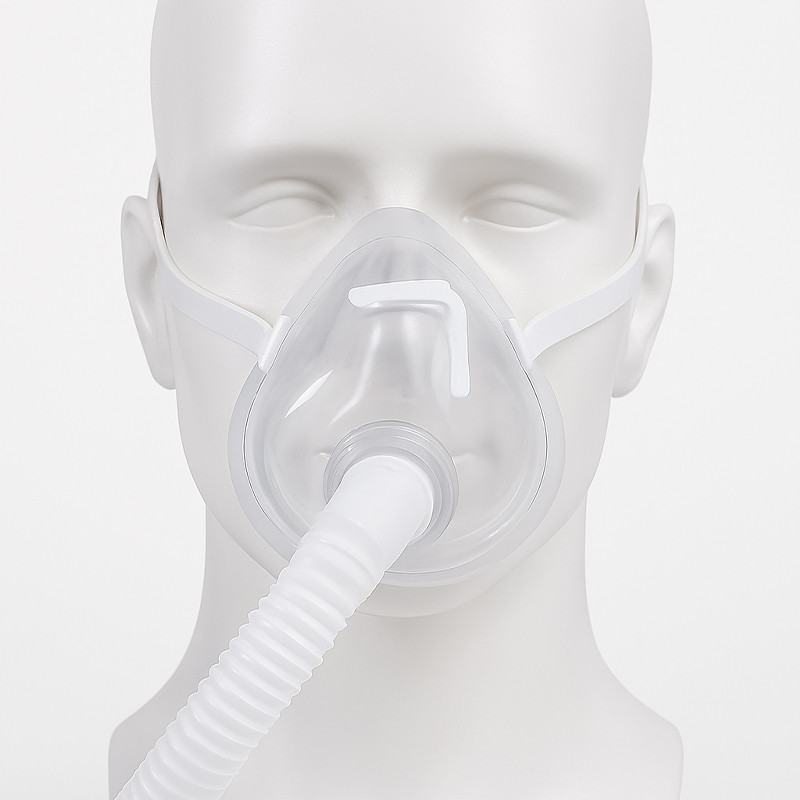

4. Personal Protective Equipment (PPE)

The COVID-19 pandemic has accelerated demand for high-quality PPE made from medical-grade LSR, including masks, gloves, and face shields.

Benefits: Superior barrier properties, comfort, and reusability.

Future Market Outlook and Growth Drivers

The global medical LSR market is projected to grow substantially over the next decade, driven by several key factors:

| Growth Drivers | Details |

| Aging Population | Increased demand for implantable devices and assistive technologies. |

| Technological Innovation | Adoption of smart materials and microfabrication techniques. |

| Regulatory Support | Streamlined approval processes for biocompatible materials. |

Healthcare Digitization | Integration of connected devices and remote monitoring systems. |

Sustainability Trends | Growing preference for eco-friendly materials and green manufacturing. |

Concluding Insights: Staying Ahead in Medical LSR Innovation

To maintain a competitive edge in the evolving medical LSR landscape, organizations must prioritize research and development, regulatory compliance, and sustainable practices. Embracing emerging trends such as smart LSR, advanced formulations, and precision manufacturing is essential for delivering innovative healthcare solutions that meet the highest standards of safety, efficacy, and environmental responsibility.

By continuously monitoring market developments, investing in cutting-edge technologies, and fostering collaborations with research institutions, industry leaders can capitalize on the tremendous growth opportunities that medical LSR presents in the next decade. The future of healthcare manufacturing hinges on adaptability, innovation, and commitment to excellence—core principles that will ensure we stay ahead in this dynamic industry.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883