Medical Grade Silicone in Wearable Medical Devices: What You Should Know

Introduction: The Critical Role of Medical-Grade Silicone in Modern Healthcare Devices

In the rapidly evolving landscape of healthcare technology, wearable medical devices have become essential tools for continuous health monitoring, disease management, and patient comfort. At the core of these devices lies a material that combines biocompatibility, flexibility, and durability—medical-grade silicone. This versatile material has revolutionized the design and functionality of wearables, providing a skin-friendly, safe, and long-lasting solution for medical applications.

In this comprehensive guide, we delve into the properties, benefits, standards, and applications of medical-grade silicone in wearable medical devices, equipping healthcare professionals, manufacturers, and consumers with the knowledge necessary to make informed decisions.

Understanding Medical-Grade Silicone: Properties and Composition

Medical-grade silicone is a specialized form of silicone elastomer formulated to meet stringent biocompatibility and safety standards required for direct skin contact and internal medical applications. Its unique chemical composition confers a combination of flexibility, resistance to environmental factors, and non-reactivity, making it ideal for long-term wear.

Key Properties of Medical-Grade Silicone

1.Biocompatibility:

Approved for prolonged skin contact without causing irritation or allergic reactions.

2.Flexibility & Elasticity:

Mimics the skin's natural movement, ensuring user comfort.3.Chemical Resistance:

Resistant to oils, sweat, and cleaning agents, maintaining integrity over time.4.Temperature Tolerance:

Operates effectively within a wide temperature range, ensuring stability during sterilization and use.5.Transparency & Colorability:

Allows for aesthetic customization and unobtrusive device design.6.Non-Toxic & Non-Allergenic:

Free from harmful substances such as latex, phthalates, and heavy metals.Manufacturing Standards and Certifications

The production of medical-grade silicone adheres to rigorous standards, including ISO 10993, USP Class VI, and FDA regulations. These standards ensure biocompatibility, sterilizability, and safety for medical applications.

Why Medical-Grade Silicone is the Material of Choice for Wearable Devices

1. Durability and Resistance to Environmental Factors

Wearable devices are exposed to moisture, sweat, UV radiation, and mechanical stress. Medical-grade silicone withstands these conditions without degrading, maintaining structural integrity and performance over time.

2. Ease of Sterilization and Maintenance

Silicone's thermal stability and chemical resistance facilitate various sterilization methods such as autoclaving, ethylene oxide, and gamma irradiation, ensuring hygienic use in clinical settings.

3. Customization and Aesthetic Flexibility

Silicone can be colored, molded, and embossed with logos or patterns, enabling brand differentiation and personalized device designs that appeal to consumers.

Applications of Medical-Grade Silicone in Wearable Medical Devices

1. Continuous Glucose Monitors (CGMs)

CGMs utilize silicone components for sensor enclosures and adhesive patches that secure the device to the skin. The biocompatibility and flexibility of silicone minimize irritation, ensuring accurate readings and user comfort.

2. Heart Rate and Fitness Monitors

Silicone straps and housings are prevalent in heart rate monitors, fitness trackers, and smartwatches. Their resistance to sweat and mechanical stress extends device lifespan while maintaining comfort.

3. Wearable ECG and Heart Rhythm Devices

Electrode interfaces crafted from medical-grade silicone enhance signal conduction and adhesion to the skin, enabling precise cardiac monitoring without discomfort.

4. Respiratory and Oxygen Monitoring Devices

Silicone's impermeability to moisture and flexibility make it ideal for mask-based sensors and breathing apparatus, providing a secure fit with minimal skin irritation.

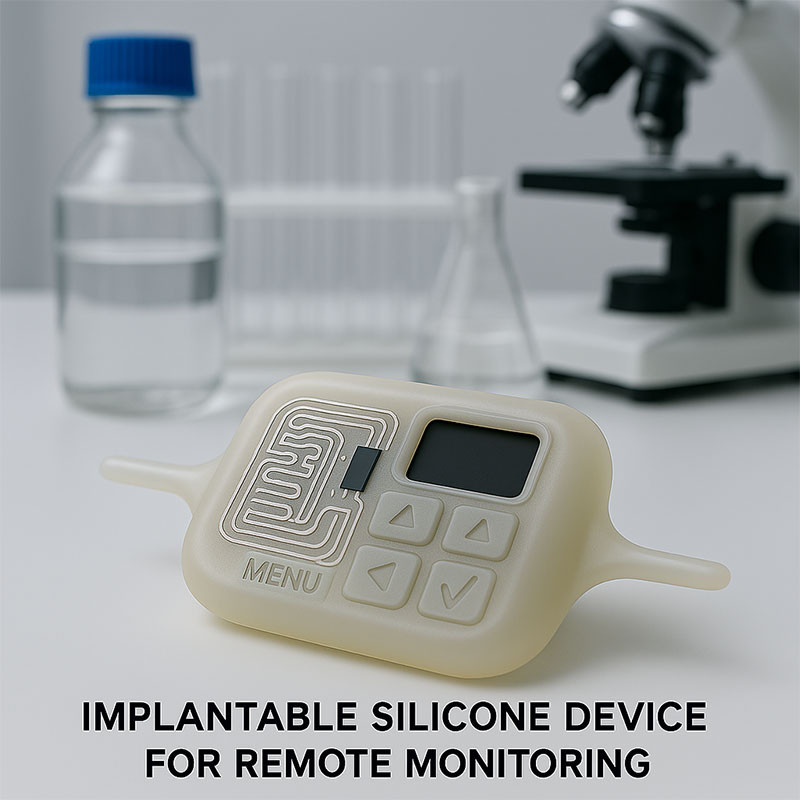

Silicone's non-reactive surface and ease of sterilization support transdermal patches and implantable devices that deliver medication or manage pain effectively.

Safety Standards and Regulatory Compliance

Medical-grade silicone must meet stringent regulatory standards to be deemed safe for wearable applications.

These include:| Standard | Description | Significance |

| ISO 10993 | Biological evaluation of medical devices | Ensures biocompatibility and safety for human contact |

USP Class VI | Testing for plastics used in medical devices | Confirms non-toxicity and stability |

| FDA Regulations | U.S. Food and Drug Administration standards | Certification for safety and efficacy in medical devices |

Manufacturing and Quality Control of Medical-Grade Silicone Components

The production process involves high-purity raw materials, precise molding techniques, and rigorous quality control protocols. Key steps include:

1.Material Selection:

Use of medical-grade silicone compounds certified for biocompatibility.2.Molding & Shaping:

Injection molding or compression molding ensures precise dimensions and smooth surfaces.3.Post-Processing:

Cleaning, sterilization, and inspection to eliminate contaminants and defects.4.Testing:

Mechanical, chemical, and biological testing per regulatory standards.The focus on traceability and consistency guarantees the reliability of silicone components in critical medical applications.

Future Trends and Innovations in Silicone for Wearable Medical Devices

1. Antimicrobial Silicone Coatings

Incorporating antimicrobial agents into silicone surfaces to prevent bacterial growth and reduce infection risks in long-term wearables.

2. Silicone with Enhanced Breathability

Developing micro-porous silicone materials that allow moisture vapor transmission, increasing comfort during extended wear.

3. Biodegradable Silicone Composites

Exploring eco-friendly and biodegradable silicone formulations to reduce environmental impact without compromising safety.

4. Smart Silicone Materials

Integrating sensor technology directly into silicone matrices for real-time health data collection and responsive device behavior.

Conclusion: The Indispensable Material for Next-Generation Wearables

Medical-grade silicone stands as a cornerstone in the design and manufacturing of wearable medical devices. Its biocompatibility, durability, and adaptability enable the creation of innovative, safe, and comfortable devices that significantly enhance patient care and clinical outcomes.

As healthcare technology advances, the role of medical-grade silicone will continue to expand, driven by research, regulatory support, and industry innovation. For manufacturers and healthcare providers, understanding the properties and applications of this remarkable material is essential to harness its full potential and deliver superior medical solutions.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883