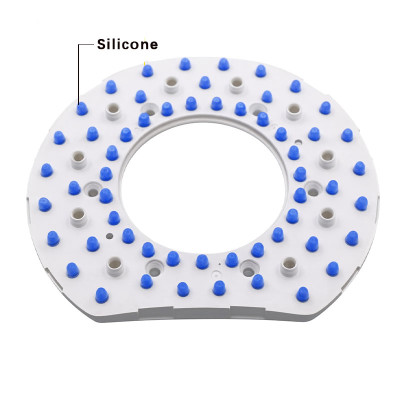

Home / All / Silicone Products / Industrial Silicone Products / High-Quality Custom Silicone Rubber Parts — Precision Molding for OEM/ODM Applications

High-Quality Custom Silicone Rubber Parts — Precision Molding for OEM/ODM Applications

Detail Information

At SiliconePlus, every silicone component starts with a simple idea:

your product deserves engineering-level precision and long-term durability.

This is why we focus on custom-made silicone rubber parts that solve real challenges across medical devices, electronics, automotive systems, wearable technology, and industrial equipment.

★ Why Companies Choose SiliconePlus

Think of us not just as a manufacturer, but as an engineering partner.

We help you turn drawings, sketches, and concepts into production-ready silicone components with:

✔ Tight tolerances as low as ±0.02–0.05 mm

✔ LSR injection molding for complex geometries

✔ Compression molding for cost-efficient mass production

✔ Overmolding for silicone-to-metal or silicone-to-plastic bonding

✔ Full OEM/ODM support from design to shipping

★ Materials That Meet Global Standards

Your industry demands reliable materials—so we only use silicone grades sourced from certified international suppliers.

Available material options:

Medical-grade liquid silicone rubber (LSR)

Food-contact safe silicone (FDA / LFGB)

High-transparency and high-elasticity silicone

Heat-resistant, oil-resistant, and UV-resistant formulas

Flame-retardant or conductive silicone for special applications

★ Designed for Real-World Performance

Whether your product needs to withstand high temperature, constant pressure, heavy use, or outdoor exposure, our silicone components are engineered to perform in tough environments.

They offer:

Excellent sealing and waterproofing

High tear strength and flexibility

Long-term resistance to heat and aging

Stable mechanical properties across extreme temperatures

Safe, non-toxic, and skin-friendly surfaces

★ Production Capabilities That Scale With Your Business

1. Rapid Prototyping

Fast samples help shorten your development cycle.

2. Precision Mold Making

Our tooling center supports multi-cavity, micro-structure, and high-precision molds.

3. Small to Large Batch Production

From 50 units to 500,000+ pieces—your order size fits our flexible system.

4. Strict Quality Control

Each batch undergoes:

Dimensional inspection

Hardness test

Tensile & tear analysis

Aging & heat resistance testing

Surface and color consistency check

★ Where Our Silicone Parts Are Used

Our components are trusted across industries:

Medical & Healthcare

Sealing valves, soft-touch pads, LSR molded parts

Consumer Electronics & Smart Devices

Buttons, protective sleeves, vibration dampers

Automotive & Industrial Machinery

Gaskets, connectors, isolation components

Wearables & Home Appliances

Flexible, skin-friendly functional parts

★ Your Idea → Our Engineering → Finished Product

Share your drawing, 3D file, or even a simple concept.

We handle the rest:

Engineering review & DFM

Material selection

Mold design

Prototyping

Mass production

Inspection & shipment

★ Ready to Create Custom Silicone Parts That Stand Out?

SiliconePlus helps you build components that elevate device performance, enhance reliability, and strengthen market competitiveness.

Let’s turn your idea into a high-performance silicone solution.

Website:www.siliconeplus.net

Email:sales11@siliconeplus.net.

Phone:13420974883

Wechat:13420974883

Related Products

Review

- Loading...

Please send your message to us

- *Phone

- *Title

- *Content

Contact Person